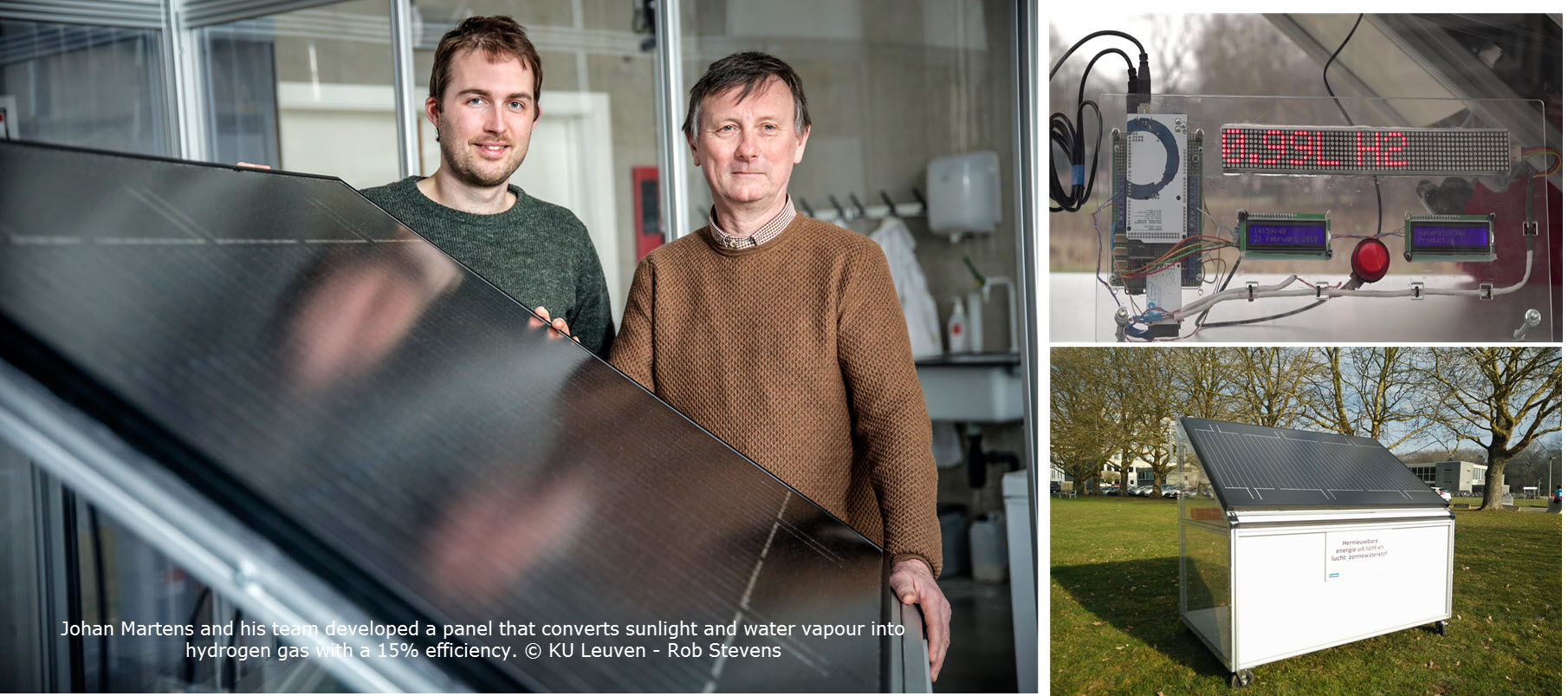

Professor Johan Martens and his team have had some pretty hectic weeks. The media interest in their new hydrogen panel has made his mailbox explode, says Martens. “The telephone hasn’t stopped ringing, and we get countless questions from journalists, fellow scientists, and even homeowners offering us their roof as a testing ground. But we’re not losing any sleep over it – unlike our colleague Jan Rongé (the third main protagonist in this story – ed.), who is probably not getting much rest: he became a father, so we’re trying not to bother him too much.” (laughs)

“In Belgium, twenty of these panels could heat and supply electricity for a well-insulated house with a heat pump all winter long.”

When we bring up the famous panel, Martens is quick to warn us: he can’t divulge too much information about the science behind the system yet. “We’ve submitted several patent applications. As long as these are still pending, it’s way too risky to give details. That’s also why we’ve barely published anything.” Nonetheless, there’s plenty to talk about, even without the technical details.

Is your team’s latest invention a new type of solar panel?

Johan Martens: “Strictly speaking: no. A solar panel converts solar energy into electricity, while our panel converts moisture from the air into hydrogen gas. Sunlight is part of the picture, of course, and our panel does look like a solar panel, but we prefer to call it a hydrogen panel.”

What makes this hydrogen panel so special?

Tom Bosserez: “Our system converts sunlight and water vapour from the air directly into hydrogen gas, with an efficiency of 15%. That’s more efficient than the traditional ways of producing hydrogen gas. In Belgian weather conditions, our panel can produce an average of 250 litres per day on an annual basis. To give you an idea: twenty of these panels could heat and supply electricity for a well-insulated house with a heat pump all winter long. If you also install a solar thermal collector and traditional solar panels, you have enough to get through the year.”

Martens: “Our technology is completely unique. Look, anyone who is familiar with what we do at the KU Leuven Centre for Surface Chemistry and Catalysis knows what our field is all about: clever combinations of adsorbents, catalysts, and membranes. But that’s all we can say at this point. Next question!” (laughs)

Martens: “Our starting point was simple: how can we produce fuel any time and anywhere? That question led us straight to the most logical answer: air, and especially the moisture it contains. Even desert air has enough water vapour in it, so you can apply this process anywhere. Water vapour is the fourth gas in the air after oxygen, nitrogen and argon, so if you find a way to catch that, you have more than enough water to split.”

“But then comes the key question: how do you get this water out of the air to split it into hydrogen gas and oxygen gas? The temperatures on a solar panel can easily reach up to 50 or even 70 degrees Celsius, which doesn’t help when you’re working with water vapour. Moreover, how do you create a system that works in the pouring rain and in situations where the humidity is very low? The biggest challenge, in other words, is the aspect of water management. Our system has a solution for that issue. But if you want to know more, you’ll have to wait a little bit longer.” (laughs)

What are the advantages of hydrogen gas as a renewable source of energy?

Bosserez: “Hydrogen gas is easy to store during the summer, allowing you to use it during the following winter. You could store the hydrogen gas in a pressure vessel, for instance. When there’s overproduction, you could also put the surplus gas on the natural gas network – similar to what we’re already doing when traditional solar panels and the electricity network produce too much electricity. This approach would require some changes to the gas network, but nothing excessive. You could even mix natural gas and hydrogen gas in the existing network for a gradual transition to pure hydrogen gas.”

Does this panel make wind farms and traditional solar panels obsolete?

Martens: “No, definitely not. Our technique complements other ways of producing green energy. The existing methods to produce hydrogen gas will still have their place. To manufacture steel or artificial fertiliser with our system, for instance, you would need a substantial number of hydrogen panels. As such, traditional electrolysis is still a better option for these industries. People who think that we’re lobbying for the hydrogen gas economy are wide off the mark, in other words.”

“A truck can’t drive from Leuven to Spain on batteries. With hydrogen as a fuel, long-distance transport becomes possible.”

Bosserez: “Our system does not necessarily compete with the batteries in electric cars, either. Batteries are ideal for short distances in light vehicles. At a certain tipping point, however, hydrogen gas becomes the better option. A truck, for instance, can’t drive from Leuven to Spain on batteries. Moreover, hydrogen gas has great potential for shipping as well.”

Is hydrogen gas dangerous?

Bosserez: “Hydrogen gas is a form of concentrated energy – as are batteries, natural gas, and petrol – so you always have to be careful. However, hydrogen gas is not more dangerous than, say, natural gas. We’ve been using natural gas in an industrial context and at home for decades now. If we gradually replace natural gas with hydrogen gas, you wouldn’t even notice the difference.”

Can hydrogen gas save the climate?

Martens: “Energy supply is not the sole cause of climate change, of course, but it’s true that hydrogen gas can play an important role in the transition to a carbon-neutral society. It’s a chemical way to reach that goal, if you will. Our system produces hydrogen gas in a carbon-neutral way: we take water vapour out of the air, use it to produce energy, and at the end of the cycle, it’s water vapour again. This is a very quick cycle, unlike the extremely slow geological cycle of fossil fuels. The cycle of biomass is too slow as well, by the way. As such, biomass is not a very interesting option for the supply of energy, but it has its use for the production of materials and green chemicals.”

Bosserez: “Did you know that most hydrogen gas is produced on the basis of natural gas? That’s why the end product is called ‘grey’ hydrogen gas. Our hydrogen panel produces ‘green’ hydrogen gas because we only use renewable sources of energy. There are several other hybrid forms with equally colourful names, by the way. These hybrid forms are still useful because green hydrogen gas is not an economically competitive option yet.”

The development of this panel has taken more than ten years. Have you ever had any doubts about the outcome of this project?

Martens (visibly surprised): “Honestly? No. It’s not in my nature to doubt myself: when I want something, I just go for it. I’m not easily discouraged either. The front pages only talk about the success stories but, in practice, science is a series of disappointments, eureka moments, and everything in between. It’s all part of the deal. It’s also crucial to find the right people, and Tom Bosserez and Jan Rongé make great team members. That helps.”

When will your technology be available on the market?

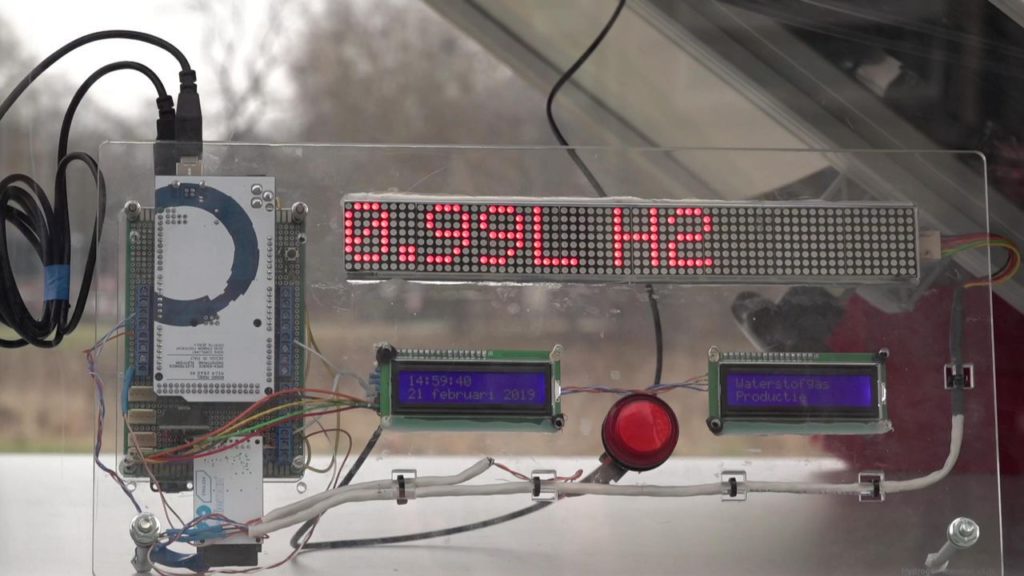

Martens: “Well, that’s hard to predict. Our hydrogen panel is far from ready for mass production. We’ve only just completed our calculations and experiments in the lab. As of this summer, we’ll be testing the panel on the roof of a house in Oud-Heverlee and on our campus to examine the impact of weather conditions, among other things. In the next two years, we’ll focus on further development. This will be done on a small scale to detect and fix any remaining flaws, and to turn it into a solid commercial product. This part of the process includes demos in various sectors, including agriculture, retail, and transport.”

“In the long term, we’re hoping to launch a spin-off company to produce the panels, in collaboration with LRD.”

“In the long term, we’re hoping to launch a spin-off company to produce the panels, in collaboration with LRD (KU Leuven Research & Development – ed.). It’s no coincidence that Reuters has already declared KU Leuven to be Europe’s most innovative university for several years in a row: our tech transfer office does a splendid job. I also have some experience with spin-offs myself: this would be my fifth one.”

How much is this hydrogen panel going to cost?

Bosserez: “At this stage, we can’t put an exact price on the panel yet, but we want to make it as affordable as possible. In any case, the raw materials for our hydrogen panel aren’t costly: we don’t need any precious metals or other expensive components.”

Martens: “Our project was very ambitious and risky, and we couldn’t guarantee its success in advance. This made it a challenge to get funding, as each selection committee receives dozens of other applications, many of them being much safer options. In 2007, however, KU Leuven gave me a Methusalem budget, which is like winning the lottery as a researcher. (laughs) The big advantage of Methusalem is that the funding spans seven years and is renewable, which means you don’t have to write so many project applications. This leaves more time for the actual research. Methusalem is awarded on the basis of past performance, among other things. That’s why the committee was prepared to take a chance on me, I think. And it has all turned out for the best.”