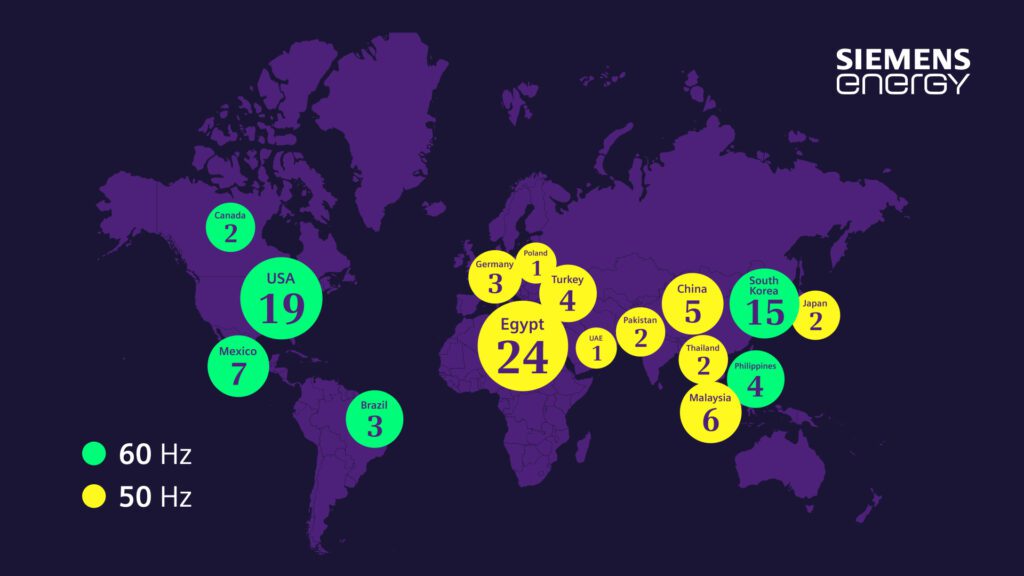

1. Siemens Energy H-class gas turbines have been installed all over the world. Notably, Egypt has the largest H-class fleet. The Egypt Megaproject, which included a total of 24 units installed at the Beni Suef, New Capital, and Burullus sites, was POWER’s Plant of the Year award winner in 2019. Courtesy: Siemens Energy

“We’re achieving a significant milestone with the one-hundredth H-class gas turbine sold,” Karim Amin, member of the executive board of Siemens Energy AG, said in a statement announcing the accomplishment. “We’re proud to see that our strategic partnerships with Guangdong Energy and Shenzhen Energy are now bearing fruit: We’ll be working together to make tangible contributions to the coal-to-gas shift efforts in the Greater Bay Area and the low-carbon development in China.”

New Chinese Gas Turbines Will Enter Commercial Operation in 2023 and 2024

Under the agreement with Guangdong Energy, Siemens Energy will deliver a 675-MW combined cycle power generation unit, including a SGT5-8000H gas turbine, a steam turbine, two generators, and related auxiliary equipment, and long-term maintenance service for the plant in Guangzhou owned by Guangdong Yuehua Power Co. Ltd. An existing coal-fired power plant will be replaced by the gas unit, reducing carbon dioxide emissions by more than 60%. The gas turbine is expected to enter commercial operation in mid-2023.

The deal with Shenzhen Energy involves three H-class combined cycle power units for the Phase II project at Dongbu power plant and an upgrade project at Mawan power plant. The scope includes three SGT5-8000H gas turbines, three SST-5000 steam turbines, three SGen5-3000W generators, and auxiliary systems. The two projects, both located in Shenzhen, are scheduled to go into operation by the end of 2023 and in mid-2024, respectively.

First H-Class Began Operation in 2008

Siemens Energy’s first H-class gas turbine—a 50-Hz unit (SGT5-8000H)—was installed at the Irsching power station in Irsching, Bavaria, Germany. The unit, Irsching 4, was first fired in 2008. Following the initial firing, the gas turbine underwent a lengthy series of tests in simple-cycle operation to prove its capabilities. After successful validation, the plant was extended to a combined cycle, and again, validated before being handed over to the customer, E.ON.

Irsching 4 entered commercial operation in 2011. The unit (Figure 2) set a new world record in power plant efficiency at the time, and was recognized as a POWER Top Plant that year.

2. With an output of more than 578 MW and an efficiency of 60.75% (net), Siemens Energy’s H-class combustion turbine installed at the Irsching 4 combined cycle power plant set world records in 2011. Courtesy: Siemens Energy

In parallel with the 50-Hz design, the first 60-Hz gas turbine (SGT6-8000H) was developed and manufactured. Validation of the 60-Hz engine took place in Siemens Energy’s testing facility located within the company’s Berlin gas turbine manufacturing plant. The first SGT6-8000H went into commercial operation in 2013 in South Korea.

Perhaps the most impressive project that Siemens Energy has completed involving H-class technology is the Egypt Megaproject, which included a total of 24 gas turbines. Completed in a record-setting 27.5 months from financial closure, the three plants—Beni Suef, New Capital, and Burullus, each with eight combined cycle units—added 14.4 GW to Egypt’s power grid. The project was recognized as POWER’s Plant of the Year award winner in 2019.

“The Megaproject was an outstanding success for Siemens Energy in various aspects,” Amin told POWER during an exclusive interview in late April. “The logistics for such a mega-project were enormous, not only for manufacturing the in-house products, like 24 gas turbines, 12 steam turbines, and 36 generators, but also to supply all Siemens Energy external products like 24 heat recovery steam generators, and to plan, build, and commission the plants as full turnkey. As a result of these enormous efforts, the plants were handed over to the customer even ahead of time and all performance guarantees were met.”

Design Improvements Continue

Amin told POWER that two elements seem to stand out in customers’ minds concerning Siemens Energy’s H-class design: reliability and performance. “The proven and reliable operation with more than 2.5 million operating hours, and the high performance being optimized for combined cycle operations with more than 62% efficiency are key criteria,” he said. “Beside this, the SGT-8000H can provide further essential features like operational flexibilities as fast starting times, high load following requirements from the grid, and minimum turndown capabilities.”

Siemens Energy has increased the output rating of the H-class gas turbine from 375 MW to 450 MW since its launch. The company has increased plant efficiency over time as well.

“The improvements have been done in various areas of the gas turbine,” Amin said. “It has always been important to apply an evolutionary approach for the SGT-8000H. This means that all modifications are rather small modifications and thoroughly validated. This has always ensured the constantly high reliability, and by keeping the main architecture constant, most of the improvements are downwards compatible and can be installed to the existing fleet as an upgrade.

“Specific modifications have been made in the compressor to allow for higher mass flow, improvements in the combustion system to allow for higher firing temperatures, and careful turbine modifications with improved cooling and coating solutions to cope with the higher firing temperatures without sacrificing lifetime of the turbine components,” Amin said. “There are further improvement steps under development but not yet released for public communication,” he added.

Market Seeks Hydrogen Co-Firing Capabilities and Siting Flexibility

As a guest on The POWER Podcast last year, Amin suggested that Siemens Energy sees hydrogen as an important piece of the worldwide effort to decarbonize power supplies. At least partly for that reason, Siemens Energy has developed a very clear roadmap to make its advanced heavy-duty gas turbines capable of operating on 100% hydrogen by 2030.

“The target of 100% in 2030 is unchanged,” Amin said during the recent interview. “In addition, Siemens Energy is constantly observing market developments—on hydrogen and other energy resources—to adapt development plans, if needed, to meet the respective market requirements.”

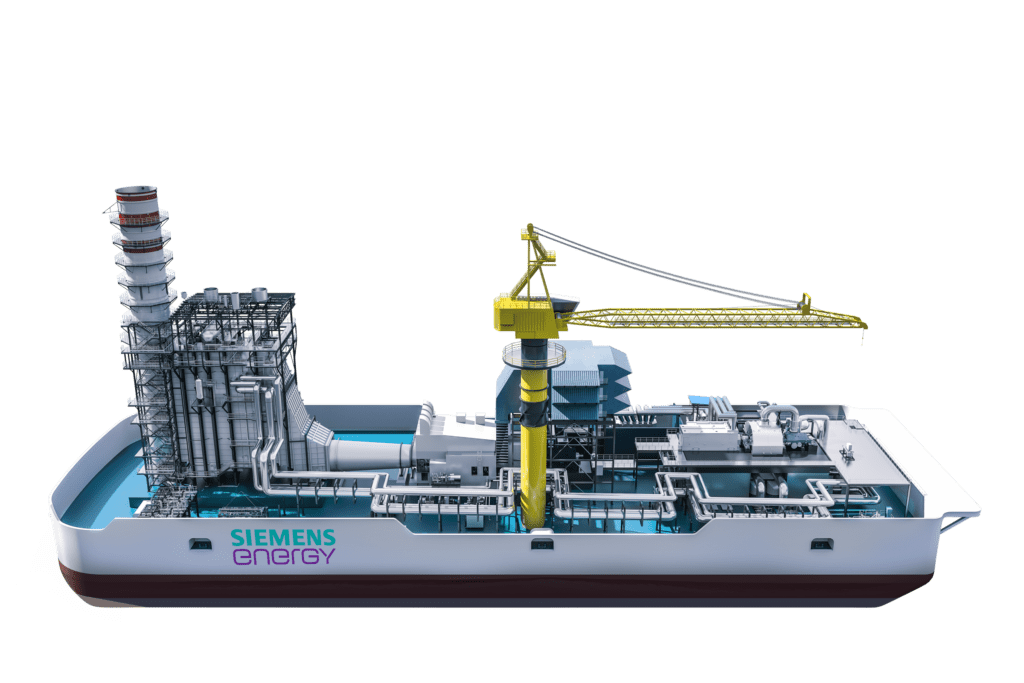

And market requirements do seem to be constantly evolving. In recent years, power companies in the U.S. and elsewhere have requested floating power plant options. Siemens Energy responded with its “SeaFloat” design, a barge-installed combined cycle power plant (Figure 3).

3. Siemens Energy’s SCC5-8000H SeaFloat power plant, pictured in this artistic rendering, has an SGT-8000H gas turbine on board. It could deliver up to 1.3 GW with a plant efficiency of more than 61% in a two-unit combined cycle configuration. Courtesy: Siemens Energy

“Siemens Energy has the capability to provide combined cycle power plants based on SGT-400, SGT-800, and H-class technology,” Amin explained. “SeaFloat power plants will be installed in a safe environment of a shipyard, and will be provided in a plug-and-play concept to the desired location. No cost-intensive land acquisition will be required,” he said.

One example of a successful SeaFloat installation is in New York City. The Astoria Generating Co. (AGC) partnered with Siemens Energy on a project announced in September 2019. AGC replaced two of four existing power barges at the 640-MW Gowanus Generating Station in the Upper Bay of Brooklyn, New York, and two other power barges at the nearby 320-MW Narrows Generating Station, with two new SeaFloat power barges each outfitted with four Siemens Energy 76-MW aero-derivative gas turbines.

“The SeaFloat power plant is designed for permanent installation at one location for the entire plant lifetime or can be relocated or resold as per customer convenience,” Amin said.