With the commissioning of Vogtle Unit 3, the USA has completed its first new reactor in decades. Featuring a Gen III+ reactor, completion of the project is a breakthrough that potentially signals a new era for nuclear power.

With the start of commercial operations anticipated any day now, Vogtle Unit 3 and its sister Unit 4 are the first new nuclear units to be built in the US in over 30 years.

As they close in on electrical generation, for the nuclear industry, the completion of Unit 3 of the Vogtle power plant marks a hugely important infrastructure investment project and for many signals a new era of US nuclear development.

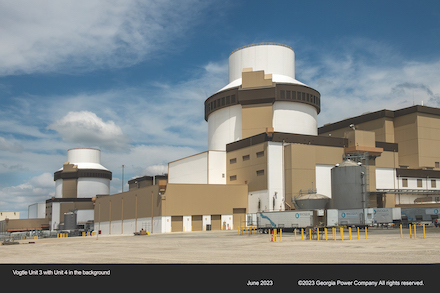

Located near Waynesboro in Burke County, east Georgia near the border with South Carolina, Vogtle 3 & 4 are the only two new nuclear units currently under construction in the United States. Each features an 1,117 MW AP1000 pressurised water reactor (PWR) from Westinghouse and, again, this is the first plant in the US to see these AP units deployed, although four AP1000 reactors – Sanmen 1 and 2 and Haiyang 1 and 2 – were commissioned in 2018 in China.

As a GEN III+ reactor, the AP (Advanced Passive) design is the first such reactor to receive design certification from the US Nuclear Regulatory Commission. As the names suggests, this design features passive safety systems that allow the nuclear core to be cooled even in the absence of operator interventions or mechanical assistance, for example. The AP1000 plant’s passive safety systems use only natural forces such as gravity, natural circulation and compressed gas to achieve their critical safety functions and no pumps, fans, diesel engines, chillers or other active machinery are necessary to maintain safety, with the exception of the valves that automatically actuate the passive safety systems.

Each of the four units features a natural circulation cooling tower for the main steam condenser and a pair of secondary, smaller, mechanical draft coolers that provide service water and cooling for reactor decay heat if necessary. Each of the main cooling towers stands at around 170 metres tall.

Units 1&2, which are 1,215 MWe reactors, were also supplied by Westinghouse. They were completed in 1987 and 1989, respectively. In 2009, the US Nuclear Regulatory Authority renewed their licences for an additional 20 years. Unit 1 is now scheduled to run until January 2047 while Unit 2 is currently licenced through to September 2049. The two new units are expected to have an operational lifespan of between 60 and 80 years, suggesting they will potentially still be operating through to the next century.

At around the same time as the licence renewal, in early 2009, Georgia Public Service Commission approved the Vogtle expansion reactors and construction activities began the same year. Initially, the units were expected to enter service in 2016 and 2017, but suffered a series of delays, including as a result of Westinghouse’s bankruptcy in 2017, that saw the projects fall several years behind schedule. Nonetheless, in 2017 Georgia Power, a subsidiary of Southern Company, contracted global engineering, construction and project management firm Bechtel to manage construction efforts of the new reactors. Bechtel operations come under the direction of Southern Nuclear, another Southern Company subsidiary, which already operates the two existing units at the Vogtle plant and will assume operational control of the two new units once they are fully commissioned.

The Vogtle Electric Generating Plant is jointly owned by Georgia Power with a 45.7% holding, Oglethorpe Power Corporation holds 30%, the Municipal Electric Authority of Georgia (MEAG) has a 22.7% stake and Dalton Utilities has 1.6% equity.

The new units are billed as an essential part of Georgia Power’s commitment to deliver ‘safe, clean, reliable and affordable energy’ for its customers. The units will also play a significant role in supporting Southern Company’s goal of net-zero carbon emissions by 2050.

Construction of Vogtle 3 & 4

The various modules used for Vogtle units 3 & 4 were manufactured in advance of arriving in Waynesboro ready to be assembled into larger components. Major modules have been arriving at the site by rail and truck since 2011. These modules have included a range of plant components such as floor and wall sections and supporting structures that surround the containment buildings and reactor vessels. The last of the 1,485 major modules required to complete construction had been manufactured and delivered to the construction site in late 2019.

Subsequently, in April 2021, all modules for both Vogtle expansion units were put in place when a large water tank, known as CB20, was lifted into its position at the top of Unit 4’s containment vessel and shield building roof. The placement also represented the last major crane lift at the project site.

This module, the Passive Containment Cooling Water Storage Tank, is a major part of the AP1000 reactor’s passive safety system. It stands some 11 metres (35 feet) tall and weighs more than 32 tonnes (720,000 lbs). The tank, which can be filled from water stored elsewhere on site, will hold some 2.8 million litres (750,000 US gals). This water tcan be used cool the reactor in the event of a cooling system failure and can also be directed into the used fuel pool if necessary.

At the peak of construction, the Vogtle 3 & 4 workforce included 1,500 Bechtel staff and nearly 7,500 members of North America’s Building Trades Unions (NABTU). With more than 7,000 workers at the Vogtle site, the project was the largest construction project in the state of Georgia, as well as a major US infrastructure development. Once the construction phase is bought to a conclusion some 800 permanent jobs will be created as the units begin commercial operations.

That day is close, Unit 3 completed Hot Functional Testing in April 2021, when the plant systems achieved normal operating pressure and temperature, although without any nuclear fuel. The first nuclear fuel assemblies for Unit 3 arrived at the site in December 2021and last October fuel was loaded into Unit 3. During fuel loading, the 157 fuel assemblies were transferred from the Unit 3 spent fuel pool to the reactor core. In March this year, operators first initiated nuclear reactions and in April,

Unit 3 first generated electricity and synchronized and connected to the electric grid. According to Georgia Power this was followed by testing through the full range of plant operations, including safely running at various power levels and operating through real-life conditions, including the operation of the reactor, plant control systems and support systems, and integrated plant operations.

After Unit 3 reached 100% power on 29 May, Georgia Power had projected a Unit 3 in-service date for the following month. However, the projects have experienced several delays as testing identified problems. Indeed, when Georgia Power received unanimous approval in December 2017 from the Georgia Public Service Commission to complete Vogtle units 3 and 4, the projected commissioning dates had been reported as expected in November 2021 for Unit 3 and November 2022 for Unit 4. Those dates have now been pushed back several times. Most recently, the in-service dates have been revised to the third quarter of this year for Unit 3 and possibly as late as the first quarter of next year for Unit 4.

Among the issues identified, in January this year, Georgia Power notified the US Securities & Exchange Commission that vibrations were detected in the plant’s cooling system. It was found during start-up and pre-operational testing that construction workers had failed to install some of the supports which had been detailed in the blueprints. While those supports have now been installed several other issues were also detected during commissioning and testing.

According to reported comments from Southern Chairman and CEO, Tom Fanning, these issues have included a dripping valve, since repaired, as well as a problem involving the flow through the reactor coolant pumps. According to Fanning, this could be a physical issue or one related to the calibration of flow measurements.

Commercial operation of unit 3 was also delayed for a month after Georgia Power noted a problem in the hydrogen system used to cool its main generator. The company said the problem was a degraded seal and the reactor was shut down while repairs are made. Georgia Power now estimates the reactor will begin commercial operations as NEI goes to press. Unit 3’s schedule ultimately also depends on potential impacts arising from unit 4 testing activities that overlap with unit 3 start-up and commissioning. The schedule also hinges on maintaining overall construction productivity and production levels, particularly in subcontractor scopes of work, and maintaining appropriate levels of craft labourers. “Any further delays could result in later in-service dates and cost increases,” the utility company said.

Meanwhile, in Unit 4 the placement of the 11 metre (35 foot) tall, 306-ton reactor pressure vessel inside Unit 4 had been completed in April 2018 while the placement of the Unit 4 containment vessel top head was completed in March 2020. More recently, in May this year, Unit 4 completed its hot functional testing programme. In a bid to avoid similar problems, lessons learned from the commissioning of Unit 3 are being applied to Unit 4. Fanning noted that there was a “marked improvement” in testing results for Unit 4 when compared with Unit 3. Kim Greene, chairman, president and CEO of Georgia Power explained: “The team at Unit 4 has been able to take lessons learned and best practices from Unit 3 and apply them. That has allowed us to safely complete hot functional testing on Unit 4 in a significantly shorter time frame than we did for Unit 3.” Nonetheless, a margin has been built into the schedule, given the experiences at Unit 3. According to Fanning, the company is “further risk-adjusting our Unit 4 schedule to reflect a range of projected in-service dates”.