Scientists from Germany’s Fraunhofer ISE and US panel maker Solaria have applied thermal laser separation and post-metallization passivated edge technology to tunnel oxide passivated contact (TOPCon) cell production. They have developed shingle PV devices that are more efficient than cells built with conventional laser scribing and mechanical cleaving methods.

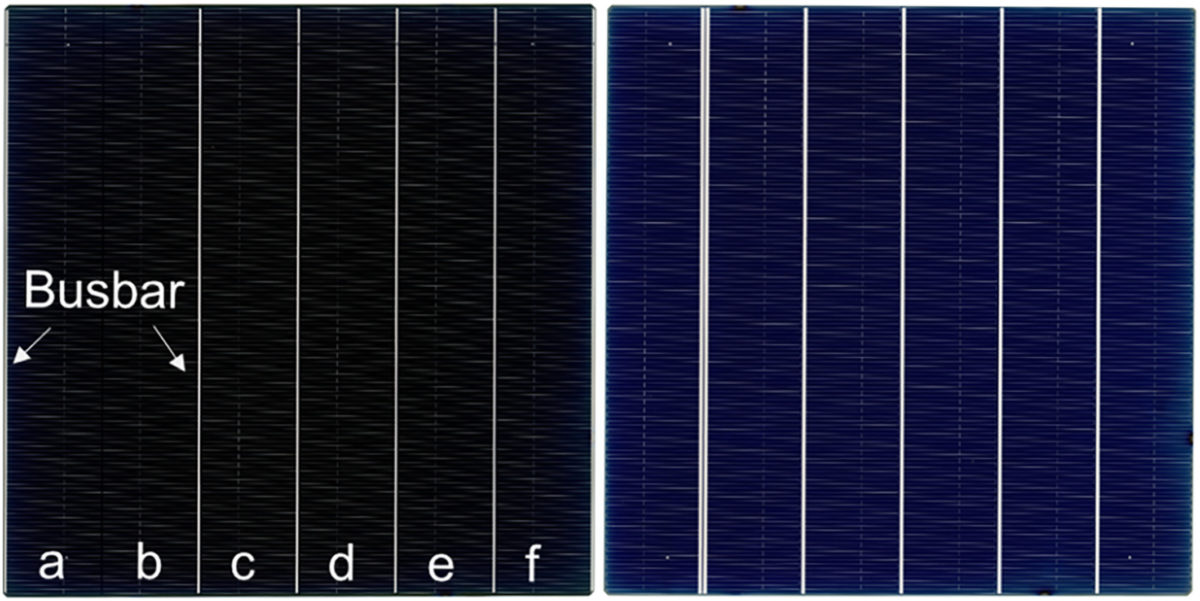

TOPCon host cell taken from the front side (left) and the rear side

Image: Fraunhofer Institute for Solar Energy Systems ISE, Progess in Photovoltaics, Creative Commons License CC BY 4.0

Scientists from Germany's Fraunhofer Institute for Solar Energy Systems ISE and US-based solar panel maker Solaria have developed a solar cell based on TOPCon technology and shingle design.

“To our best knowledge, this is the first publication dealing with TOPCon shingle solar cells separated by thermal laser separation (TLS) and edge-passivated by the passivated edge technology (PET),” researcher Elmar Lohmüller told pv magazine. “The PET is a proprietary development of Fraunhofer ISE, to address the cutting losses in today‘s half-cut, third-cut, or shingle solar cells, by simple, high-throughput post-processing of singulated cells.”

Fraunhofer ISE filed a patent application back in 2018 and is offering a sampling of the technology for interested partners. Solaria is one of the first industry partners testing post-metallization PET on TOPCon shingle solar cells.

“The PET approach could address a key need of the industry – to mitigate efficiency losses incurred by cell cutting and do so in a cost-effective way,” Ricky Dunbar, a Solaria spokesperson, told pv magazine. “Our cooperation with Fraunhofer ISE has shown that PET can effectively reduce these losses for TOPCon shingle cells at a promising throughput.”

The proposed manufacturing process uses thermal laser separation (TLS) instead of conventional laser scribing and mechanical cleaving (LSMC) for cell singulation. TLS only requires a short initial laser scribe with a cleave laser and water-air aerosol jet to create a starting crack that can then propagate through the wafer in any direction.

“This results in cuts with very smooth edge surfaces,” the scientists explained, noting that TLS was performed via the microDICE laser system developed by Germany's 3D-Micromac.

“The TLS process optimized in this work yields up to 0.2% more efficient shingle cells directly after separation in comparison with shingle cells that have been singulated by LSMC,” the academics said, noting that the cell based on TLS achieved a power conversion efficiency of 22.0% “It is shown that TLS can be performed such that no degradation of the surface passivation quality occurs in the vicinity to the dividing line.”

The research team introduced its findings in “TOPCon shingle solar cells: Thermal laser separation and passivated edge technology,” which was recently published in Progress in Photovoltaics.

“As we are still in the development phase of an industrial PET tool, valid data for yield ratios of the two approaches for a reliable cost calculation is not sufficiently available, yet,” Lohmüller said. “Nevertheless, PET will add a process step, which to our current knowledge is easily scalable to current throughput demands, thus the demonstrated gain in efficiency has substantial potential to overcompensate the additional cost.”