Cars can increase fuel efficiency by replacing steel with aluminum, carbon fiber or other strong, lightweight materials.

The COVID-19 pandemic prompted much of U.S. manufacturing to shut down, contributing to the recent drop in U.S. energy use.

While the shutdown likely has reduced industrial emissions substantially, it comes at an awful and unsustainable cost. Two new peer-reviewed studies, one representing 28 organizations worldwide and the other led by my organization, suggest a much better way to cut industrial emissions that also will help get the economy back on track.

A sweeping plan is essential. We cannot truly tackle climate change without slashing industrial carbon emissions (decarbonizing) by mid-century. Industry accounts for one-third of global greenhouse gas emissions, and its U.S. emissions are projected to grow more than those from any other end-use sector. Within industry, manufacturing is a particularly big emitter and it has the largest impact on the U.S. economy.

Congress would be wise to consider manufacturing in future stimulus and other funding. It could invest in transformative measures that put people back to work while also offering long-term climate benefits.

For example, it could deploy teams of experts to the 500 largest U.S. carbon-emitting industrial facilities to do energy audits, fund R&D efforts at the U.S. Department of Energy’s Advanced Manufacturing Office, and use incentives and other tools to promote low-carbon products. These efforts would boost the United States’ manufacturing competitiveness.

Decarbonizing industry will demand a mix of policies and technologies, ranging from tax incentives and carbon pricing to electrification, low-carbon fuels and carbon capture and use, according to a paper I recently co-authored in the journal Applied Energy.

Energy efficiency is a critical pathway. As my organization’s research explains, currently available efficiency measures can cut industrial emissions 15 percent and also reduce costs, boost resilience and create jobs. This entails more than smart energy management and energy-efficient buildings and equipment. We will need a whole-systems approach that uses technologies such as sensors, advanced low-carbon materials and integrative design.

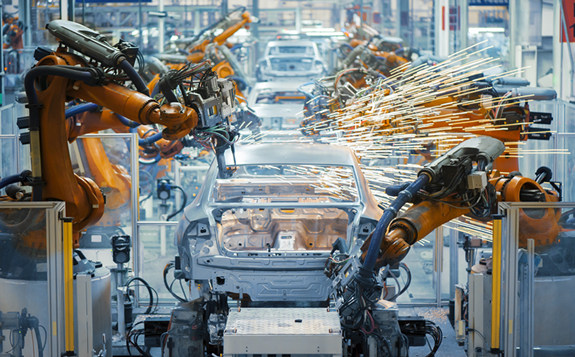

Within industry, manufacturing is a particularly big emitter and it has the largest impact on the U.S. economy.

For example, Interface reduced energy use in a Dutch carpet factory by not only using more efficient pumps and motors but also making pipes fat, short and straight, which slashed pipe friction losses allowing them to downsize the pumps and motors.

A whole-systems strategy may extend beyond individual facilities to entire industrial parks. In fact, a 2014 study found that an eco-industrial park with a steel mill, cement plant, fertilizer plants and recycled paper facility achieved 21 percent energy savings because of heat integration and combined use of co-products.

We also will need to focus on supply chains. All along supply chains, greenhouse gasses are emitted as goods are produced, distributed, used, reused and disposed of. Because manufacturers both buy and make energy-intensive equipment, they can help drive demand for low-carbon materials and goods. We also need to focus on the dozen or so sectors that account for 90 percent of industrial emissions, including the three biggest global emitters: cement; iron and steel; and chemicals.

The good news? New products, including alternative concretes, low-GHG steel and novel chemical catalysts, show promise for reducing carbon emissions. In fact, technologies such as automation and techniques such as light-weighting of products are transforming how we make everything, from smartphones to airplanes.

For example, cars can increase fuel efficiency by replacing steel with aluminum, carbon fiber or other strong, lightweight materials, and buildings can reduce their amount of concrete by using curved fabric molds instead of standard shapes with sharp angles.

Additive manufacturing, known as 3D printing, can reduce lead time, inventory cost and materials scrap. Wood fibers and straw can be used for insulation, and wood can be used instead of steel and concrete in many low- and medium-rise buildings. As recently built office towers exceeding 275 feet in Austria and Norway show, glued-and-laminated timber can work even in high-rise buildings.

Much more needs to be done, especially by policymakers. Governments should pursue labeling and procurement of low-carbon products, data collection and disclosure requirements, and recycling incentives.

A good next step toward industrial decarbonization is the CLEAN Future Act framework, released by the U.S. House Committee on Energy and Commerce.

It incorporates approaches that we and other advocates have sought, including carbon capture, storage and use, a Buy Clean Program for low-carbon construction materials in projects receiving federal funds and a climate or green bank. It proposes a nationwide Clean Electricity Standard, sets national energy savings targets for buildings and supports strong state energy efficiency standards. My organization will continue its effort, begun more than a year ago, to convene NGOs, industry stakeholders and labor to develop a detailed roadmap for decarbonizing industry.