Energy supplies should begin no later than the second quarter of 2025. The supply contract is for 20 years, with an agreed annual purchase volume of just under 100,000 MWh of thermal energy. The heat will be produced at a new biomass heating plant being built on an industrial road in Dingolfing, at a site in direct proximity to BMW Group vehicle plant 02.40, between the Dynamics Centre and the A92 motorway.

Since 2010, the Dingolfing public works department has operated a biomass heating plant in the southeast of the city that supplies public buildings and private households with heating. The new heating plant will be realized in conjunction with E.ON company Bayernwerk Natur through the joint subsidiary UP Energiewerke GmbH, in which both partners hold a 50% stake.

The heating plant will have three boilers operating year-round, as well as its own pallet and waste-wood shredder. UP Energiewerke GmbH will invest a total of around €35 million in this facility over the coming years. Underground pipes will carry the locally produced heat to the energy center at BMW Group vehicle plant 02.40, where it will be distributed across the site through the plant’s internal network. Construction of the heating plant is scheduled to begin in late 2023.

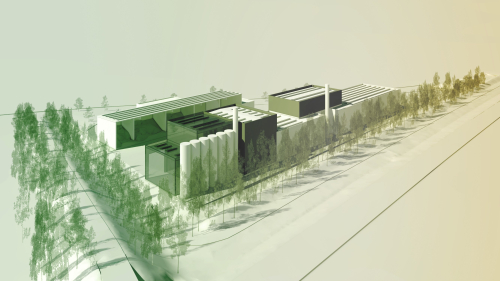

Rendering of the biomass heating plant.

About a quarter of the wood used as fuel will come from the BMW Group’s own untreated waste wood—for example, from single-use pallets and transport crates. However, most of the wood will be obtained from regional forestry, i.e. from sustainably-managed PEFC-certified forests within an average radius of 60 kilometers from Dingolfing.

As with the existing heating plant in Dingolfing, the partner for procuring wood is Biomasse Vertrieb Ostbayern (BVO) GmbH, which is backed by local forest owners and the Dingolfing public works department. The wood used as fuel is a by-product from forestry and timber harvesting that cannot be utilized elsewhere. Available in large quantities, this was often previously exported abroad in the form of wood chips. Using wood chips from sustainable forestry instead of fossil fuels to produce energy, helps lower CO2 emissions, since the CO2 released during combustion is bound from the atmosphere during the growth and life phase of the plants.

Bavarian forestry will face enormous challenges over the coming years as climate change continues to progress. Largely coniferous stands must be converted to climate-stable mixed forests by planting more deciduous trees and changing tree species. Young trees must also be tended in the early stages and mixed growth regulation promoted, in favor of climate-resilient tree species. For this reason alone, over the coming decades, considerable amounts of waste wood will be generated from both regular use and salvage logging that can be recycled in a meaningful and economical way in the energy sector. With the new heating plant as a consumer, we will be able to keep value creation local. The use of regional biomass makes environmental sense and ensures shorter distances for transportation and recycling. In the interests of sustainability, we will, of course, only take what can grow back every year in our forests.

—Anton Heidobler, a forestry engineer and managing director of BVO GmbH