The Hydrogen Micro Hub is a facility that produces hydrogen by applying a high-temperature electrolysis process with solid oxide electrolysis cells (SOEC) to the electricity and high-temperature steam generated by USNC’s Micro-ModularReactor (MMR). This is a carbon-free hydrogen production method that extracts hydrogen by decomposing water with electricity generated from nuclear power.

Source: USNC

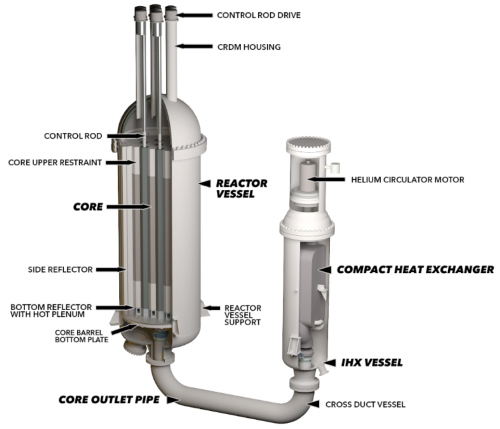

The MMR is a 4th Generation High Temperature Gas-cooled Reactor with output from 5-10 MWe and 15-30 MWth; demonstration units are scheduled for first nuclear power in 2026. Multiple MMR units can be linked together to provide as much power as needed.

Under the agreement, the three companies will jointly conduct research and development on the MMR-SOEC integrated plant for the next five years. Through this, they plan to examine the establishment of a competitive hydrogen production system, and promote continuous research and development and verification for future hydrogen production and supply businesses.

Hyundai Engineering will oversee the MMR-related BOP (Balance of Plant) and EPC (Engineering, Procurement, and Construction) activities, while USNC will be responsible for MMR design, manufacturing, and supply. SK E&C will establish a nuclear power-based hydrogen production system using Bloom Energy’s SOEC and supply hydrogen production equipment.

In this project, Hyundai Engineering and USNC will utilize a micro modular nuclear power plant based on the high-temperature gas-cooled reactor (HTGR) being demonstrated at the Chalk River Laboratories Campus in Ontario, Canada. Compared to commercial pressurized water reactors, this technology can generate relatively high-temperature steam, enabling the use of SOEC operating at high temperatures, which can maximize hydrogen production efficiency with less energy.

SK E&S has successfully tested hydrogen production through electrolysis using a 130 kW-scale SOEC facility located at the Bloom SK Fuel Cell manufacturing plant in Gumi, Gyeongsangbuk-do, in cooperation with Bloom Energy and Bloom SK Fuel Cell.

It is also participating in a government-led green hydrogen production demonstration project. The company is also pursuing a project to convert green hydrogen into ammonia or methanol. It is evaluated as having a complete renewable energy-based green hydrogen value chain, from renewable energy project development to related equipment production and EPC to green hydrogen production. In addition to this Hydrogen Micro Hub cooperation, SK E&S is diversifying its “zero carbon emission hydrogen production model” to include pink hydrogen, which is produced by electrolyzing water using electricity from nuclear power generation.