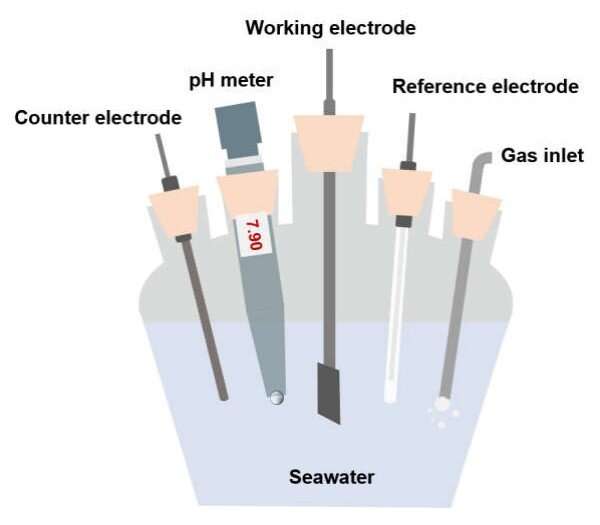

Schematic diagram of three-electrode configuration for seawater electrolysis. Note that the pH meter was placed 1.0 cm from the electrode surface to measure the pH of the bulk seawater near the working electrode. Credit: Nature Energy (2023). DOI: 10.1038/s41560-023-01195-x

A team of engineering and materials scientists from China, Australia and the U.S. has developed a process for using sea water to produce hydrogen without having to first pretreat the water. In their paper published in the journal Nature Energy, the group describes their new process and how well it worked compared to other processes that involve pretreated water.

As climate change progresses, scientists around the world continue to look for replacements for fossil fuels. One promising replacement is hydrogen, which does not produce greenhouse gases when burned. Much of its promise is due to the fact that water is used as the base product, which is plentiful in the world's oceans. But producing hydrogen tends to be expensive.

The primary means for this process is electrolysis, in which electricity is used to break apart the hydrogen and oxygen that make up water molecules. One of the reasons the process is expensive is the need for pure water, which can involve deionization and desalinization and also the addition of materials such as alkalis. In this new effort, the research team found a way to carry out electrolysis on untreated sea water in a way that they claim is inexpensive.

Producing hydrogen via electrolysis also requires the use of a catalyst, which unfortunately generally involves the use of rare precious metals, driving up the cost of production. In this new effort, the researchers used a non-precious-metal catalyst—a transition metal coated with a layer of chromium oxide. And rather than treating the sea water, the team simply filtered it to remove microorganisms and solids.

The researchers found that the process was close in performance to current systems that require pretreatment of water and expensive catalysts—and it was also nearly 100% efficient. They acknowledge that more work is required to make sure there are no side reactions occurring over larger spans of time. They will also need to test how well their process scales up to larger systems and to ensure there are no hidden costs.