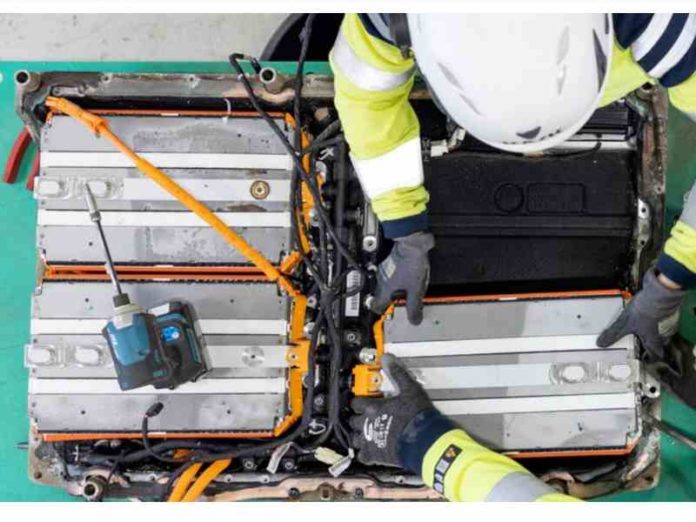

Fortum battery recycling. Courtesy Fortum.

According to the battery recycling tech company, their newly established company in Germany aims to address the European automotive and battery manufacturing industry’s rising demand for battery raw materials.

The new recycling hub for ‘end-of-life’ lithium-ion (li-ion) batteries and wastes from battery manufacturing is expected to start its operations by the end of 2022, in the industrial cluster at Baden-Wurttenberg in southern Germany.

The news comes in as the role of lithium-ion batteries within the energy transition has been placed under scrutiny.

According to the epa (United States Environmental Protection Agency), the batteries’ demand has been steadily increasing due to their high energy density, although its chemistry mix can have harmful repercussions. If not properly managed at the end of their life, they can cause harm to both human health and the environment.

Tero Holländer, the company’s head of business line, batteries, elaborated on the implications of the tech within the European market: “For a fully electric car lithium-ion battery, you need approximately 50kg of nickel, 8kg of lithium and 7kg of cobalt [which illustrates] the challenge of the raw materials shortage in Europe. For the EV and battery sector to be sustainable, we need to recover raw materials from the battery production process in the most sustainable way.

“[Fortum’s] low-CO2 battery recycling solution makes it possible to recycle over 80% of the battery, and 95% of the valuable metals contained in the battery’s black mass can be put back into circulation”, Holländer added.

“We are bringing our competencies and superior battery recycling technology into the heart of the European automotive market to provide on-site services to companies operating within the automotive and battery industry. We will offer our low-carbon recycling technology in Germany, leveraging industrial synergies with the automotive and battery manufacturers”, stated Kalle Saarimaa, vice president, Fortum recycling and waste.

Fortum’s battery recycling

According to Fortum, the recycling process begins when the lithium-ion batteries are first disassembled and treated during a mechanical process at Fortum’s plant in Ikaalinen, Finland.

The mechanical processing enables the recovery of plastics, aluminium, copper and black mass. The battery’s black mass, containing critical metals, is collected and then taken for hydrometallurgical processing at Fortum’s plant in Harjavalta, Finland, from where it can be fed back to the European battery value chain.

The hydrometallurgical recycling process involves a chemical precipitation methodology that allows scarce minerals to be recovered from the black mass and delivered to battery manufacturers for reuse in the production of new batteries.

Other recovered materials are recycled in separate processes.

The Germany-based battery recycling operations are planned to allow Fortum to help bridge the raw materials gap the automotive industry is facing, which is even more in focus with the upcoming EU-wide battery regulation that is expected to drastically increase the quantity of recycled raw materials in new batteries.