Westinghouse Electric Company signed MOUs with seven companies to potentially deploy the company’s AP1000 nuclear reactor for the Dukovany 5 project in the Czech Republic. Westinghouse is one of three finalists for the job.

The companies involved are Královopolská, which provides technological steel structures, such as load-bearing equipment structures or platforms; Vítkovice, an engineering group which supplies modules for nuclear power plants; I.B.C. Prague, which develops, produces and services industrial valves for the nuclear and energy industry; I&C Energo, an electrical and engineering company which services command-and-control systems and industrial information systems; NOPO, which specializes in gantry cranes, paint shop platforms, manipulators and overhead cranes; Sigma Group, which produces medium, heavy and unique centrifugal pumps designed for use in energy management; and Infer, which specializes in piping systems, valves and metallurgical material.

Westinghouse Electric Company signed memorandums of understanding with seven companies in the Czech Republic (Source: Business Wire).

The MOUs, signed at the Ministry of Industry and Trade, also extend to other potential projects in Central Europe.

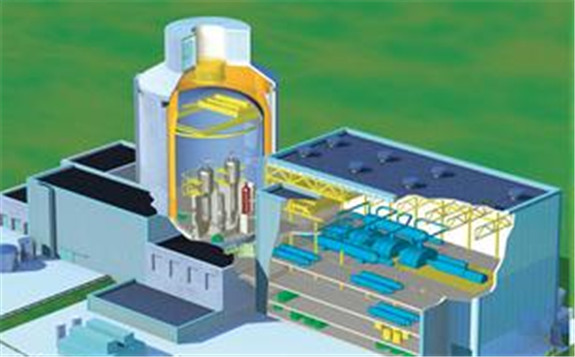

The AP1000 is a two-loop pressurized water reactor (PWR) which evolved from previous Westinghouse PWR designs, created more simply with fewer components to help cut capital costs and reduce the need for large cooling towers and other equipment. The reactor was created to produce a net electrical output of 1,117 MWe.

The reactor coolant system includes two heat transfer circuits, with each containing one steam generator, two reactor coolant pumps, and a single hot leg and two cold legs for circulating coolant between the reactor and the steam generators. The system also includes a pressurizer, interconnecting pipes, and the valves and instrumentation needed for operational control.

Unlike previous generations, the AP1000 plant’s passive safety systems do not require an operator in the event of a design-basis accident, like a coolant-pipe break. Rather than relying on active components, such as diesel generators and pumps, the AP1000 plant relies on natural forces – gravity, natural circulation and compressed gases – to keep the core and the system from overheating. No pumps, fans, diesels, chillers or other active machinery are used, except for a few valves that automatically align and actuate the passive safety systems.

Westinghouse’s AP1000 design was certified by the U.S. Nuclear Regulatory Commission in 2005. The company currently has six AP1000 nuclear plants operating or under construction. Four are operating at two separate sites in China: two at Sanmen Nuclear Power Station and two at Haiyang Nuclear Power Plant.

There are also two AP1000 units under construction at the Alvin W. Vogtle Electric Generating Plant near Waynesboro, Georgia. Construction at Vogtle has been bogged down by numerous delays and rising costs. In December 2021 project engineers told the Georgia Public Service Commission Vogtle Unit 3 wouldn’t meet the completion range of July 2022 to September 2022 set by Georgia Power, who shares ownership of the project. Engineers told state regulators a more accurate completion target might be November 2022 to February 2023. They said Unit 4 may not come online until sometime in late-2024.

When they go into service, Vogtle units 3 and 4 would be the first new U.S. nuclear generation reactors since Watts Bar 2 began operating in 2015.

Plans for two other AP1000 reactors at the Virgil C. Summer Nuclear Plant in South Carolina were canceled in 2017. The decision came after a comprehensive evaluation of the project following Westinghouse’s bankruptcy. The Toshiba subsidiary filed for bankruptcy, citing over $6 billion in debt.