“We mainly use the production line in Sweden for collector development and to demonstrate to potential buyers how the Absolicon T160 is manufactured,” said Joakim Byström, Managing Director of Absolicon. The collector is designed for use within large solar fields. It can produce heat and steam in multiple industries or be connected in series to flat plate collectors to boost the temperature in a district heating network.

Order from South Africa

Just recently, Absolicon has signed a framework agreement with Greenline Africa, based in South Africa, to put up a production line with an annual capacity of 100,000 m². It has been the second order for a production line made by the company. The first was commissioned in China’s Sichuan Province in October 2018.

A 26 June news article on South African website esi-africa.com put the contract value at an estimated EUR 4 million, plus a monthly license fee of 4 %. The contract terms also include training staff to operate the line, as well as planning and designing additional concentrating solar heat systems.

Greenline Africa is a newly founded company offering sustainable energy solutions. Byström said that Absolicon was in talks to become a minority shareholder in the business. “We see a market for T160s in South Africa among small food processing businesses that use expensive electricity or large producers that want to get away from coal,” he added.

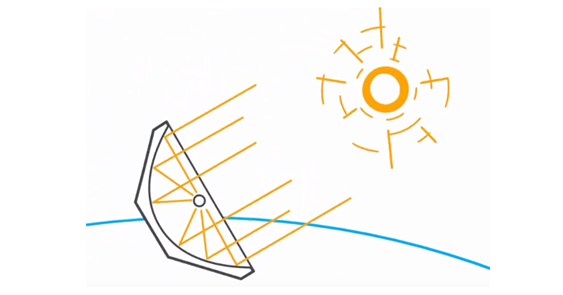

T160 tracking the sun: A steel structure coated with a reflective film focuses sunlight onto a stainless-steel receiver tube. Back ribs keep the reflectors in position, while a glass cover protects them against soil and dust.

Chart taken from the short film at https://www.absolicon.com/anim_02en

“Greenline Africa will initially produce the Absolicon T160 by importing most components, such as receivers, steel reflectors and glass covers,” explained Byström. “But, step by step, more of them will be sourced locally to reach 70 % in the long run.”

Tested across the full temperature range to 160 °C

The Solar Keymark certificate for the T160 collector was issued in February. It has been the first concentrating collector certification since 2013 when several technologies, including air and concentrating collectors, were incorporated into global test standard EN ISO 9806. “The test results from Swiss research institute SPF showed a high optical efficiency, µ0, of 76.4 % based on the beam irradiance of the surface aperture area,” Byström pointed out. The publicly available Solar Keymark certificate shows an optical efficiency of 69.7 % based on beam irradiance and gross collector area.

Byström was satisfied with the performance tests at SPF. “In our experience, Solar Keymark test procedures are well suited for assessing the performance of concentrating collectors,” he said. At SPF, the T160 was tested across the full temperature range, all the way up to 160 °C, and the assumptions in the quasi-dynamic model held true. “SPF’s findings will enable us to make performance estimates with the same accuracy as for flat plate solar collectors,” he added.

Absolicon has uploaded an animated video to show customers what rigorous durability tests the T160 collector had to pass to become Solar Keymark-certified. In one of those, the glass cover had to withstand a load of over 500 kg; in another, the collector was subjected to hailstones with a diameter of up to 25 mm.