HALEU - uranium enriched to between 5% and 20% uranium-235 - will be used in the advanced nuclear fuel required for most of the next-generation reactor designs currently under development. The US Department of Energy (DOE) has been supporting measures to ensure the availability of the material for those reactors when needed, and also to build a domestic HALEU supply chain.

"With HALEU, advanced reactors can get increased fuel in-core lifetimes because you have higher enrichment," said Adrian Wagner, a metallurgical engineer and INL's Advanced Manufacturing group lead. "In simple terms, higher enrichment means more uranium-235 atoms in each pellet."

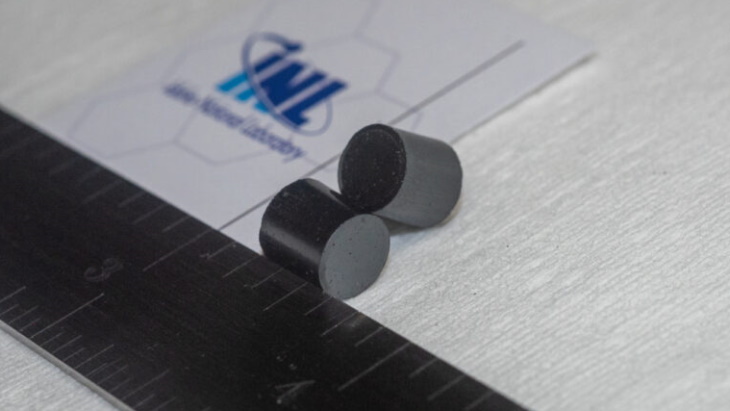

The HALEU fuel pellets made at INL's Experimental Fuels Facility contain fuel enriched to 15% uranium-235 and are "an important step in the testing and qualification process", INL said. The pellets were made at lab-scale using a traditional powder metallurgy process - a pressure-less sintering technique similar to that used by industry to make light water reactor fuel.

It noted that demonstrating the capability to fabricate a commercial quality of uranium dioxide (UO2) HALEU provides options for industry and other government agencies to make fuel samples with a wider range of enrichment without impacting existing operating licenses.

The researchers are performing tests to further characterise the pellets' properties and identify impurities.

Collaboration with GE

The team at INL plans to fabricate 100-150 pellets to be irradiated in the Advanced Test Reactor.

The work, in collaboration with General Electric, will test the endurance of a prototype of cladding material that could improve the performance of existing light water reactors and future advanced reactors. This project is being funded under the DOE's Accident Tolerant Fuel Program, an industry-led effort looking to commercialise new fuels within the decade.

"The bigger picture is that it will help the licensing of advanced reactor designs, almost all of which will use some form of HALEU fuel," Wagner said.

Demonstrating UO2 HALEU fabrication "opens the door for other types of HALEU, both metallic and ceramic, and highlights INL's ability to tailor enrichments to customer and experiment requirements," INL said. It noted that nitride, boride, carbide and silicide fuels have higher uranium densities that could provide even higher levels of performance for advanced reactors.

"Our collaborators were pleased with the outcome," said Jennifer Watkins, a nuclear fuels and materials scientist at INL who led the project. "The pellets that we produced were extremely high density. Our initial characterisation efforts suggest they will meet all commercial standards for uranium dioxide.

"INL is the best place in the US to develop fabrication processes for unique and novel fuel concepts. INL has one of the widest ranges of feedstock options at a variety of enrichment levels and an extremely flexible DOE-based enrichment license allowing for adaptability to user needs."

Earlier this month, Centrus Energy delivered the first HALEU produced at its American Centrifuge Plant in Piketon, Ohio, to the DOE. Construction of the 16-centrifuge demonstration cascade plant began in 2019, under contract with the DOE. The delivery by Centrus of more than 20 kilograms of HALEU to the DOE means that phase one of the contract has now been completed and Centrus can move ahead with the second phase: a full year of HALEU production at the 900 kilograms per year plant. In this phase of the contract, the DOE will pay Centrus on a cost-plus incentive fee basis for the HALEU the company produces. The HALEU which DOE has taken delivery of will remain on site in Piketon in a specially constructed a storage facility until it is needed.