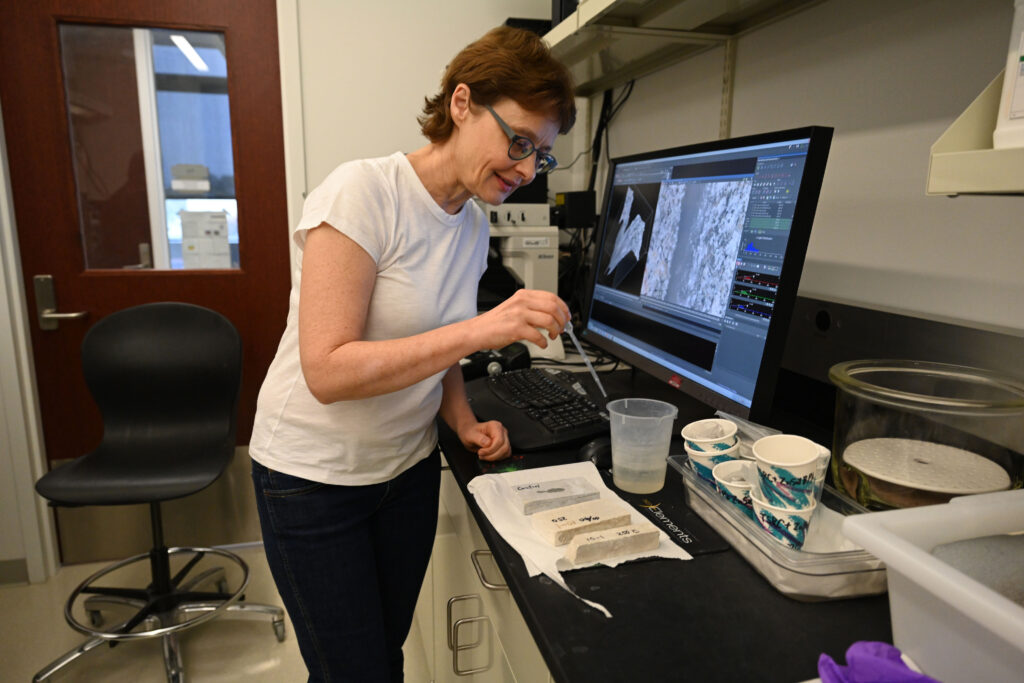

Brookhaven National Laboratory materials scientist Tatiana Pyatina will lead a newly funded DOE Energy Earthshot Research Center aimed at developing sustainable materials for geothermal wells. (source: Brookhaven National Laboratory)

Brookhaven National Laboratory materials scientist Tatiana Pyatina will lead a newly funded DOE Energy Earthshot Research Center aimed at developing sustainable materials for geothermal wells. (source: Brookhaven National Laboratory)With this selection, the new research center is set to receive funding of USD 19 million over four years for their work on exploring the chemical and mechanical properties of cement composite and other materials used in enhanced geothermal systems (EGS). The research will inform the design of Earth-friendly varieties of cement composites, coatings, and other barriers designed to protect geothermal wells.

“Geothermal energy has the potential to transform abundant heat trapped deep underground into gigawatts of electricity for powering millions of American homes. It is renewable, has a small geographical footprint, and, unlike other green energies [e.g., wind and solar], is available around-the-clock,” said Brookhaven Lab materials scientist Tatiana Pyatina, who leads the geothermal materials research effort at Brookhaven Lab and will direct the new C4M EERC.

Improving the performance of cement composites

One of the challenges in geothermal projects is the selection of cement composites used to construct the wells, as they need to be able to withstand extreme temperatures and the corrosive nature of geothermal fluids. This is even bigger challenge in EGS projects, as wells are expected to experience even greater thermo-mechanical stresses. In addition, the process of cement production is an extreme carbon dioxide (CO2) emitter.

“To realize geothermal energy’s potential, it is therefore essential to rationally design cost-effective, sustainable well-construction materials with a net-zero CO2 footprint,” Pyatina said.

The C4M team will be testing new cementitious composite materials to understand the chemical changes that take place under high temperature and pressure, informing the design of reliable and durable composites for use in extremely challenging underground environments. One of the objectives is to learn to control the solidification and transformations of these materials so they can be deployed successfully and economically in well construction and operation.

“Our hope is that this research will achieve our goal of developing net-zero CO2 materials that will cut the cost of enhanced geothermal systems by 90% by 2035,” added Pyatina.

A multi-disciplinary approach

The high heat requirements (if powered by fossil fuels) and the limestone decomposition reaction make the process of cement production a CO2-emitting process. To avoid these CO2 emissions, the C4M team will be exploring the use of alternate minerals, possibly even the mud used to drill the wells, which would form its own cement in place.

The team will seek to identify materials with geologically stable mineral phases, or may even consider the use of inorganic coatings that can create pipe-like well casings more resistant to high temperatures and aggressive environments. Some coatings may protect the metal casings so well that cement would no longer be needed.

To achieve this, the team will use both laboratory experiments and computational modeling to analyze and predict the performance of these new composite materials from the atomic to the macroscopic scale, and for a time span ranging from seconds to years. “We have assembled a multi-disciplinary team of leading researchers with complementary expertise,” Pyatina said.

The research will leverage expertise and DOE Office of Science user facilities at Brookhaven—including the National Synchrotron Light Source II (NSLS-II) and Center for Functional Nanomaterials (CFN)—as well as at partner institutions, including the Advanced Light Source at DOE’s Lawrence Berkley National Laboratory. Additional partners include DOE’s Sandia National Laboratory, DOE’s Lawrence Livermore National Laboratory, DOE’s Los Alamos National Laboratory, and four universities: University of Texas at Austin (a minority-serving institution), Cornell University, University of Illinois Urbana-Champaign, and Princeton University.

“Through this Center, an incredibly talented team has been assembled to develop the fundamental understanding of the materials needed to push back the pressure and temperature boundaries of geothermal power production,” said Thomas Butcher, a research engineer who leads the energy conversion group in Brookhaven Lab’s Interdisciplinary Science Department.