Image: Siemens Energy

Carbon capture, utilization and storage (CCUS) technology isn’t new and it’s been much maligned and overlooked. Yet Daniel Hofmann of Siemens Energy says that is changing. He explains why, and also makes the case for CCUS as an essential ‘no regrets’ technology to achieve climate change targets and to future-proof power plants.

Teesside was once home to the world’s first steam-powered public railway and the industrial heartland of the UK, with iron, steel and chemical manufacturing dating back to the early 1800s.

Two-hundred years on from its industrial birth, this region in the northeast of England will soon be at the forefront of the green industrial revolution.

It will be the location of a new ground-breaking project that can be considered a lighthouse for modern power plants with carbon capture.

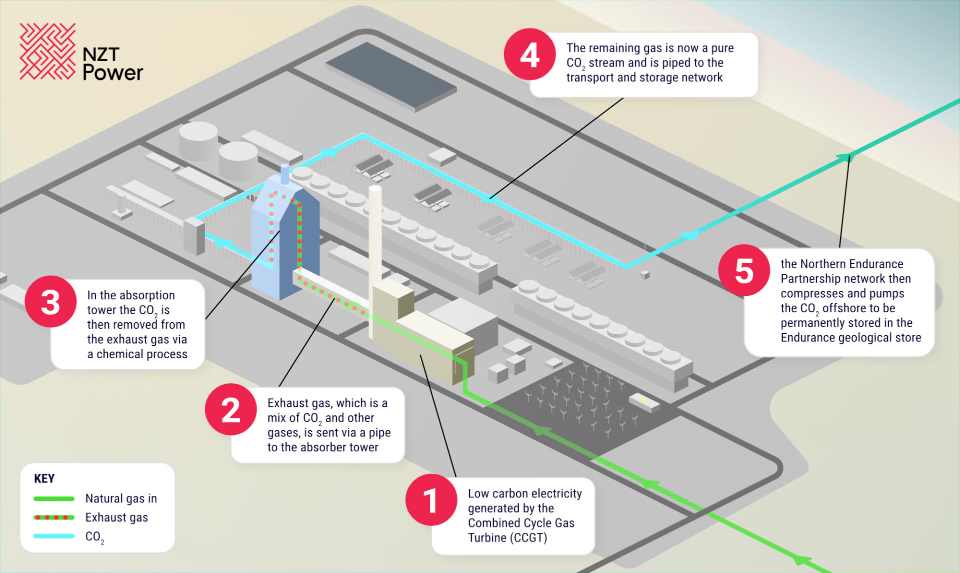

Net Zero Teesside Power (NZT Power) is a first-of-its-kind commercial-scale gas-fired power station consisting of an 860MW combined-cycle power plant, with an H-class gas turbine, integrated with carbon capture, utilization and storage (CCUS).

The plant will sit within the East Coast Cluster, a collection of industrial, power and hydrogen businesses across Teesside and the Humber which also aim to decarbonize their operations with CCUS.

The project was greenlit by the UK government in March 2023 and a final investment decision is expected in 2024.

What is CCUS?

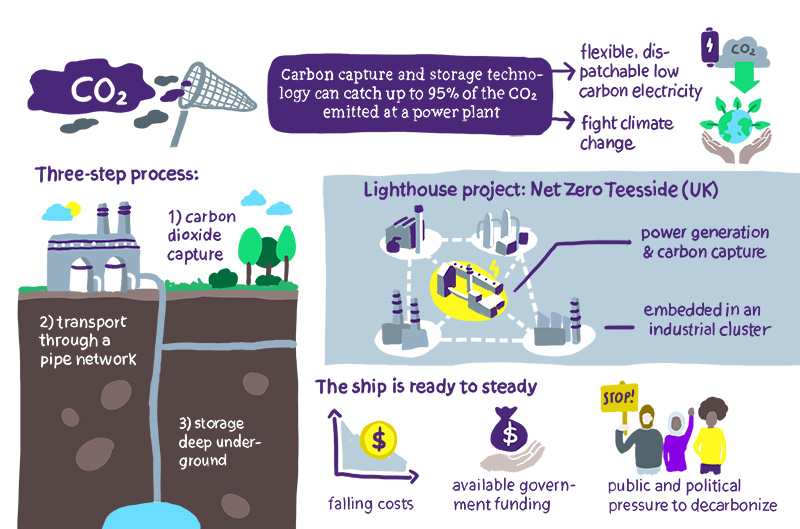

CCUS refers to a suite of technologies that can capture the CO2 of large point sources. In simple terms, it’s a three-step process: carbon dioxide is produced by power generation or industrial activity is captured; if not being used on site, it’s transported through a pipe network or across land; and finally, it is stored deep underground.

What it is not, is new.

Some facilities have been operating CCUS since the 1970s and 1980s and, today, the technology currently captures 45Mt CO2 annually globally.

Decarbonising the power system by 2035

Nevertheless, as the International Energy Agency notes, the deployment of CCUS is far behind what is required in the net-zero scenario. Even when considering all projects in the pipeline, some 300 in various stages of development. This adds to NZT Power’s relevance. Designed for rapid start-up, the plant will produce enough electricity to power 1.3 million homes.

Ninety-five per cent of all emissions produced – around two million tonnes of CO2 a year – will be captured, dried, and compressed.

Common infrastructure provided by the Northern Endurance Partnership will then transport the captured CO2 from NZT and other decarbonisation projects within the East Coast Cluster to secure a geological store 145km offshore in the North Sea.

The project will help support the UK government’s commitment to fully decarbonize its power system by 2035 and provide jobs and an annual gross benefit of up to £450 million ($557 million) for the region. It’s expected to be completed by around 2027.

Why is CCUS needed?

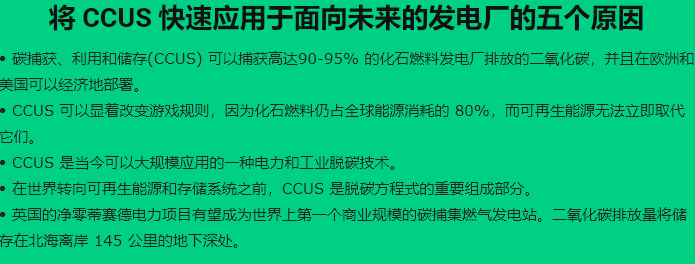

It’s fair to ask, why is CCUS needed when renewables are being deployed rapidly and at scale?

The answer is straightforward. Around 80% of global energy consumption currently relies on fossil fuels and dispatchable power. Given demand is projected to grow by nearly 50%, immediately swapping out all gas for renewables is not practical. Besides CCUS, another method for decarbonising conventional power generation is through renewable hydrogen and other green fuels (i.e. e-ammonia and e-methanol).

However, none are expected to be affordable for the power sector for some time, with most commercial supply likely to first be absorbed by other sectors.

Additionally, dispatchable low-carbon energy, such as gas-fired power with CCUS, can support an increase of intermittent renewable energy.

It provides flexibility and backup generation to the energy mix – crucial for periods when the wind isn’t blowing, and the sun isn’t shining.

Considering this, until the world achieves new levels of energy efficiency and shifts completely to a renewable energy and storage system, it’s clear CCUS is an essential part of the decarbonisation equation.

Diving into the CCUS technology

The most mature carbon capture technology is amine-based absorption. It can capture up to 95% of carbon emissions and is considered economically deployable in Europe and the US.

It works by flue gas – the mixture of gases produced by the burning of fuel in power stations – being fed into an absorption column.

Here, an amine-based solvent strips out the CO2. The CO2-rich solvent is then fed into a regenerator, with a temperature of 120 degrees Celsius, to reverse the process. This produces pure CO2 and regenerated solvent. The former is transported for use or storage and the latter is returned to the absorption column.

To deploy the technology at a combined cycle power plant, there are some technical considerations. For example, the configuration will remain the same, but the steam turbine must be partly adapted. Retrofits and brownfield sites must be upgraded and refurbished, often with a new steam turbine fitted. As steam is used in the capture and separation process operators must also consider where this will come from.

Additionally, the process produces heat which can either be used within the plant or for heating adjacent infrastructure via heat pumps.

Lastly, a control system is needed, possibly one that integrates the power system and CCUS to work together.

On the storage side, location is a determinative factor. All oil and gas exporting countries have the potential to use retired oilfield wells; carbon use for enhanced oil recovery has been done in the US for years, accounting for around 5% of the nation’s oil production.

There is also the possibility for storage in saline aquifers, as has happened successfully at the Sleipner gas field carbon capture and storage project since the late 1990s.

At the site, around one million tonnes of captured CO2 a year is stored in the Utsira sandstone, a saline aquifer formation of extensive and highly porous sandstone filled with saltwater.

In the future, it’s possible there will be more advanced CCUS technologies available; engineers frequently come up with new chemistries and approaches for capture. These may include enhanced gas recirculation to improve the efficiency of the capture plant and enhanced reactors with a better exchange of the washing media and the flue gas.

The working of NZT Power – a lighthouse example of a partnership approach to CCUS. Image: NTZ Power

The importance of a partnership approach

For delivering CCUS projects, one thing is clear; rolling out these solutions requires the expertise and collaboration of various companies.

In fact, most of the industry is already taking a partnership approach, including the East Coast Cluster.

BP, the operator of NZT Power and the Northern Endurance Partnership, is working with Siemens Energy, carbon capture provider Aker Solutions/Aker Carbon Capture, and project design and construction company Doosan Babcock, to deliver one of two competitive comprehensive front-end engineering design packages, expected to be completed in the coming months. The selected consortium will work on the construction of the project.

Siemens Energy doesn’t offer carbon capture technology; however, it can construct the power plant, partner with those building the capture plant and integrate the two technologies together. It also offers compression technologies needed for some capture models and for transportation and sequestration.

The partnership approach can also prove useful when problem solving, an inevitable part of the process as the technology is rolled out in the real world.

The economics of CCUS

Today, how to economically deploy CCUS has become a bigger question than the validity of the technology.

Governments are tentatively starting to throw their weight behind the process.

The UK is taking a leading approach. The Northern Endurance Partnership is creating the transportation and storage infrastructure, meaning not every project capturing CO2 – big or small – will be responsible for investing in this phase, improving the economics for those projects.

What’s more, the bespoke Dispatchable Power Agreement for power plant CCUS, is designed to incentivise the availability of low carbon, non-weather dependant dispatchable generation capacity by offering an ‘availability payment’.

This can also help accelerate projects by providing revenue certainty.

Seeing the clear benefits, other regions are also looking to the cluster approach.

In Germany, where climate goals have put CCUS back on the table, the government is developing a Carbon Management Strategy for CO2 storage and utilization. It’s also looking to the industrial cluster approach to reach economies of scale.

Norway is also targeting heavy industries and looking to develop an open access infrastructure with the capacity to store significant volumes of CO2 from across the continent.

Of course, there is still uncertainty and challenges to overcome; it will likely be necessary to transport carbon over borders, especially in Europe, which can present problems.

Additionally, some countries, such as Germany, are historically opposed to domestic carbon storage.

Mechanisms that can drive the market

There is one certainty, however. The industry needs stability to thrive. Projects with long lead times that cost hundreds of millions will not cope with changing legislation and boundary conditions.

Many projects have already failed simply because, suddenly, something changed. Stability is what the industry craves, but unfortunately, is not yet a reality; changes are happening faster than in recent decades.

Perhaps, in some ways, this is good, given the direction they are headed – towards faster decarbonisation. Nevertheless, in this environment, first movers are likely to be nervous.

There are signs the ship is ready to steady, however.

Although occasionally prone to significant changes, forecasts for Europe’s Emissions Trading Scheme price are on an upward trend. It could be argued, they are already where they need to be to justify investment in CCUS technologies.

Public and political pressure to decarbonize is likely to grow stronger with policies such as the incoming Carbon Border Adjustment Mechanism, which puts a price on carbon for some goods entering the EU, and is timed with the phase-out of free allowances under the Emissions Trading Scheme.

Currently, 94% of industrial emissions are covered by free allowances which has muted the carbon price signal, reducing the incentive to invest in technologies like CCUS.

Additionally, government funding is becoming available for CCUS projects: in the US, tax credit amounts nearly double for CO2 that’s captured from power and industrial plants; in the UK, £20 billion ($24,8 billion) of state funding has been earmarked.

These policies and initiatives can help de-risk projects and aid considerable cost reduction.

What’s more, the industry can continue to learn from the projects that are realised, driving down risks and overall costs for those next in the pipeline.

The future role of CCUS

Going forward, it’s likely there will be both big and small CCUS projects making it online in the coming years.

When the industry has had time to take stock of them, more investment and more projects will come and costs will fall – there’s an estimated 25% reduction possible with increased deployment.

It’s vital these projects materialise. At the end of March, the UN’s Intergovernmental Panel on Climate Change issued its strongest warning yet; act now or it will be too late to meet the global ambition of limiting warming to 1.5 degrees (above pre-industrial levels).

The message is clear. The current project trajectory we’re on won’t be enough. The industry must move today to make CCUS at scale a reality. The Paris Climate goal – and indeed, our future – depend upon it.

HOW TO…Fast-track CCUS to future prof power plants\]

ABOUT THE AUTHOR

Daniel Hofmann is the Director of R&D and Portfolio and Product Line Management at Siemens Energy. He is covering plant integration across the whole conventional power generation spectrum. In his 28 years in the industry, he has worked in most fields of power generation, oil&gas, and decarbonisation. He is teaching at the University of Erlangen-Nürnberg.