Lithium-ion batteries are currently the gold standard in battery technology, but as the demand for safe and effective batteries increases, researchers are racing to find what's next.

All-solid-state lithium batteries could be an alternative to current lithium-ion battery technology, but improvements in their capacity are needed.

A new study led by researchers from the Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT) of the Chinese Academy of Sciences details how ferroelectric cathode coatings boost the capacity of all-solid-state lithium batteries.

The study was published in Advanced Functional Materials on March 28.

Ferroelectric materials possess an inherently polarized electric field that is widely used to accelerate the separation and transfer of charges in many electrochemical types of research.

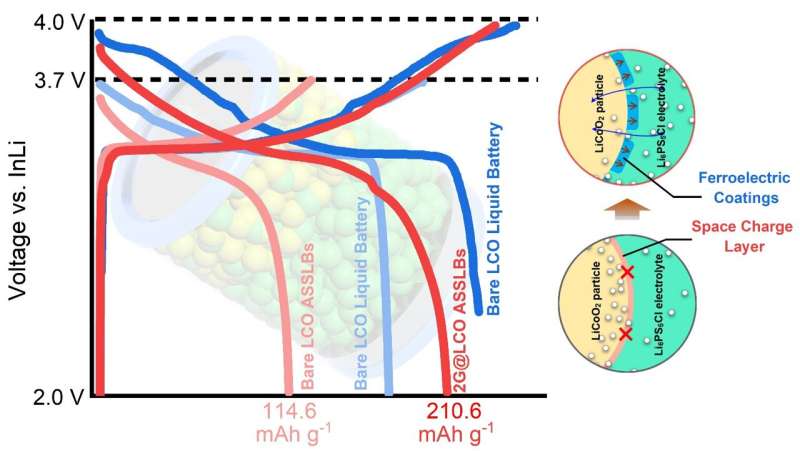

"In the field of all-solid-state lithium batteries, it is widely accepted that the ferroelectric polarization induces the built-in electric field at the electrode/solid-state electrolytes interface, which could suppress the space charge layer and boost lithium transportation," said Dr. Li Wenru, first author of the study. "However, the construction mechanism of the ferroelectric built-in electric field in these batteries is poorly understood. Revealing this construction mechanism becomes a critical challenge."

To understand more about how the ferroelectric material improves battery function, the researchers covered the lithium cobalt oxide cathode in a coating layer made from an organic-inorganic hybrid ferroelectric material called guanidinium perchlorate. Guanidium perchlorate coatings were found to possess a single-domain state, meaning the inner ferroelectric dipoles point to one same direction. This behavior finally generates the downward built-in electric field at the cathode/electrolyte interface. Guanidium perchlorate can be made by evaporating solvents like ethyl alcohol, making it an inexpensive and environmentally friendly option for battery manufacturing.

The researchers found out that the capacities of the all-solid-state lithium batteries with the ferroelectric coating on the cathode are nearly the same as current liquid lithium-ion battery, which is much higher than the all-solid-state lithium batteries using the uncoated cathode.

They also analyzed how the active particles interacted with the electrolyte in the cathode with and without the coating. A space charge layer, which interferes with the movement of electrons through the battery, forms when the lithium cobalt oxide meets the solid-state electrolyte. The space charge layer restricts the transport of the lithium and reduces the capacity of the battery. When the coatings were coated onto the cathode, the effective ferroelectric built-in electric field made the lithium move more fluently through the cathode/electrolyte interface, improving the capacity of the battery despite the space charge layer.

"We found that the flexoelectric effect caused by the lattice mismatch is the primary factor for the self-polarization effect of the coatings. Our study not only designs the all-solid-state lithium batteries with excellent electrochemical performance, but also discovers the scientific theoretical guidance for constructing the ferroelectric coating layers in promoting performances of electrochemical energy storage," said Dr. Li.

Looking ahead, the researchers will look at different combinations of materials to expand the possibilities for all-solid-state lithium batteries. "We hope to expand this research idea to different combinations of cathode and ferroelectric materials in future work, and obtain experimental rules for optimal battery performance," said Prof. Cui Guanglei, corresponding author and the group leader of Solid Energy System Technology Center at QIBEBT. "The ultimate goal is to have a universal strategy improving lithium battery performance in practical applications."