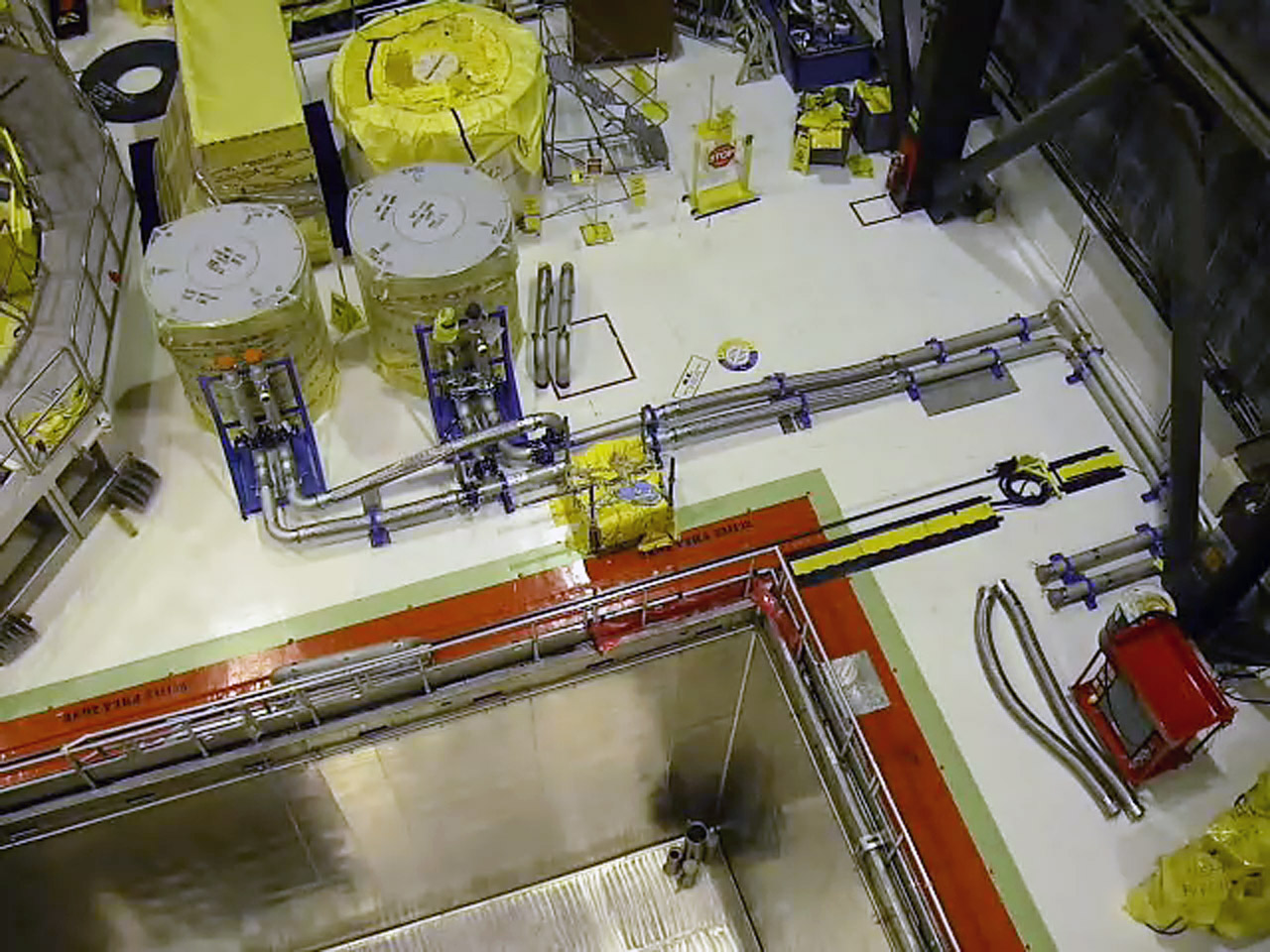

BWR spent fuel pool dual SCF system with shields.

The return of low natural gas prices combined with the advent of high efficiency renewables has placed more pressure on nuclear power plant operators to reduce their operational and maintenance costs and to increase plant availability while continually meeting the increasing number of safety and regulatory requirements. Outage management is a key factor for good, safe, and economic nuclear power plant performance; it involves detailed planning and preparation as well as the application of proven advanced technologies for completing task activities. Outage tasks frequently require the use of pure, high clarity water. Traditional filtration technologies used for maintaining clarity have long been the bane of many nuclear plant operators. Poor water quality in the fuel pool and reactor cavity can cause high radiation exposure, and high turbidity can lead to the slow-down or complete stoppage of underwater work activities.

Traditional in-plant filtration systems are not meant to handle the transient load of suspended solids present during outages and other special maintenance operations. Many operators come to rely upon nuclearized “pool vac” type filtration units to maintain water clarity, but these units suffer from poor contaminant removal efficiency, short filter run-times between filter element replacement, or both. Observing an industry need for improved filtration, AVANTech engineers began researching and testing differing filter mediums in a variety of configurations; the result of their efforts is AVANTech’s Solids Collection Filter™ (SCF™) that has now been deployed and relied upon by a multitude of commercial nuclear utilities and governmental nuclear facilities for maintaining water purity in fuel pools, reactor cavities, emergency cooling systems (torus, suppression pools, and refueling water storage tanks), and for a variety of other online and outage related filtration and waste packaging activities.

AVANTech’s Solids Collection Filter (SCF™)

Filtration Technology

The SCF™ uses proprietary filter technology in a configuration that enables it to remove incoming insoluble solids by mechanisms such as gravimetric separation, adsorption, and size exclusion. By incorporating multiple mechanisms, the SCF™ can operate at very high flow rates (1,000 gpm) and with a tremendous solids holding capacity (≥1,000 pounds). When these traits are combined with the SCF™’s nuclear-friendly modularity, remote handling, use, and dewatering features, then you have the ultimate filter!

Application Experience

The SCF™ was first applied to maintain clarity in large torus/suppression pools at boiling water reactors that can range up to approximately one million gallons. Prior to the SCF™, plant operators applied a train of small filters that were marginally effective at maintaining water clarity when divers stirred up settled debris during various work activities. Particularly troubling was the inability of these systems to recover from loss of water clarity. Poor visibility sharply reduces diver productivity while increasing radiation exposure due to longer stay times, increased number of dives, and higher ambient dose rates. The shortcomings of these systems were compounded by the fact that divers needed to frequently replace expended filters, which involved manual removal, bagging, and transport to a drop off area – all dose intensive activities. Later, these filters had to be handled again when they were surveyed, characterized, and packaged as radioactive waste for disposal.

Compared to predecessor technologies, the SCF™ has a 10-fold higher filtration rate and a 100-fold higher solids loading capacity; these improvements enable it to maintain clarity throughout a campaign or project without the need for changeout or replacement, thus saving critical path time, personnel radiation exposure, and money. Due to its success, the SCF™ has been used in many other applications over the past 12 years; a few examples are described as follows:

The challenges of liquid radioactive waste treatment and solids packaging are diverse and plentiful. AVANTech has developed a variety of unique technologies, like the SCF™, to effectively meet these challenges. All of these technologies fulfill fundamental requirements that create client value, including less material handling, improved safety, shortened project schedule, reduction in radiation exposure, decreased liquid and solid waste generation, and project cost savings.

AVANTech personnel are skilled in all aspects of liquid and solid waste treatment and packaging with a robust NQA-1 program. To get more information on AVANTech products or to have one of our experienced engineers configure a treatment system that specifically meets the challenges at your facility, please reach out to us.