Imagine, if you will, a lightweight, inexpensive power source with 9 times the energy density of a lithium-ion battery. Got your mind wrapped around that concept? Now imagine that power source uses recycled aluminum, one of the most abundant metals on Earth, and an electrolyte so nontoxic you can drink it.

Call this power source a battery. Call it a fuel cell. Call it whatever you like. It is an invention that could upend energy storage as we know it and drive the electrification of transportation — from bicycles and neighborhood electric vehicles to heavy trucks, airplanes, and cargo ships — forward at warp speed.

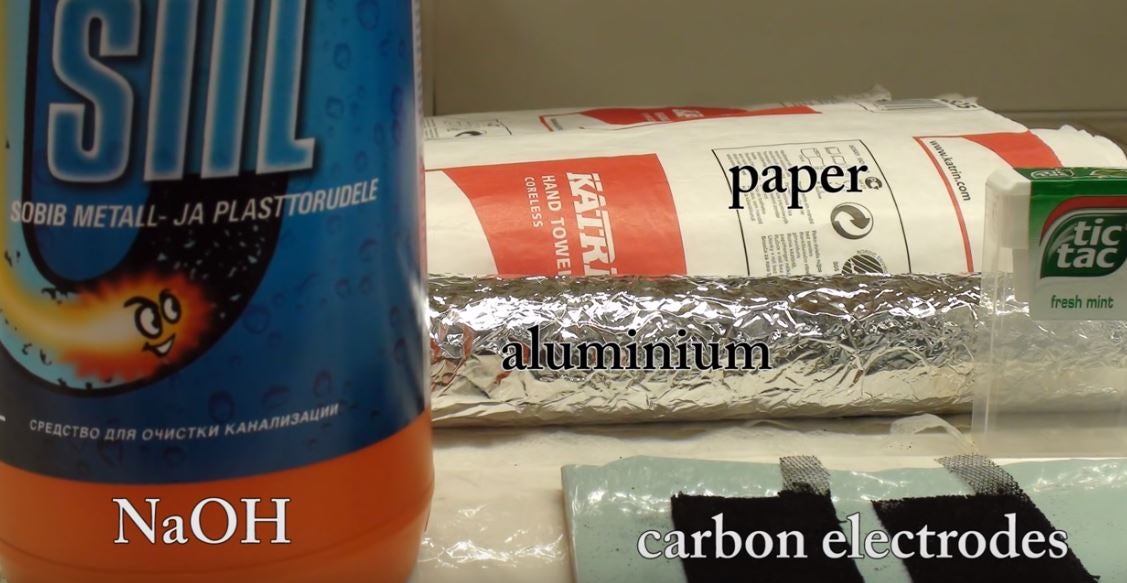

The person behind all this is UK engineer and former Royal Navy officer Trevor Jackson, who began experimenting with aluminum air batteries at his workshop in the Cornish town of Callington in 2001. At that time, the electrolyte used was extremely caustic and poisonous. After years of experimentation, Jackson devised a new electrolyte — whose composition is a closely guarded secret — he says make it possible for his invention to power an electric car for up to 1,500 miles.

What happens when it runs out of juice? You replace it with a new one while the old one gets recycled. At the beginning of the electric car era when charging infrastructure was nonexistent, the idea of swapping spent batteries for fully charged new ones was considered feasible. Jackson says such a thing could be the future, with his batteries/fuel cells sold at grocery stores and retail outlets. He says the process of disconnecting the old one and connecting the new one will take about 90 seconds.

But is it tin foil hat time? Is this story just another example of some crackpot inventing some radical new product that defies conventional physics, like cold fusion? Lots of people think so, and in fact Jackson says powerful forces have attempted to prevent his idea from reaching a larger audience. But an independent evaluation by the UK Trade and Investment agency in 2017 said Jackson’s invention was a “very attractive battery” based on “well established’” technology, and that it produced much more energy per kilogram than standard electric vehicle types, according to a report in the Daily Mail.

Some comparisons are in order. A Tesla Model S can drive up to 370 miles on a single charge. Jackson says if you drove the same car with an aluminum-air cell that weighed the same as the Tesla’s lithium-ion battery, it would have a range of 2,700 miles. Aluminum-air cells also take up less space. If that same Tesla were fitted with an aluminum-air fuel cell the same size as its current battery, it could run non-stop for 1,500 miles.

Jackson says the battery for that long range Tesla Model S costs about £30,000. Tesla aficionados will probably quibble with that number but Jackson claims his aluminum-air battery/fuel cell that could power the same car for longer would cost just £5,000. Of course, if the owner has to spend £5,000 every 1500 miles, the economic case for the new energy source is compromised somewhat. Time will tell.

Multi-Million Dollar Deal Is Signed

Think this is all crazy talk? Consider this. Jackson has just signed a multi-million dollar deal with Austin Electric, an engineering firm based in Essex which now owns the rights to use the old Austin Motor Company logo. It will begin putting thousands of them into electric vehicles next year. According to Austin’s chief executive, Danny Corcoran, the new technology is a “game-changer. It can help trigger the next industrial revolution. The advantages over traditional electric vehicle batteries are enormous.”

Jackson has also secured a £108,000 grant for further research from the Advanced Propulsion Center, a partner of the Department for Business, Innovation and Skills. His technology has been validated by two French universities. He says: “It has been a tough battle but I’m finally making progress. From every logical standpoint, this is the way to go.”

Austin Electric has three targets for the new batteries — the three-wheeled tuk-tuks used for transportation in many countries such as Pakistan, electric bicycles with far more range than current models, and a program that will convert front wheel drive cars with internal combustion engines into hybrids by fitting aluminum-air batteries and motors to drive the rear wheels.

Jackson expects the conversion operation to start next year. He says the cost of each conversion will be £3,500 or about $4,000. He thinks this will be a proof of concept “stepping-stone” phase in the transition to aluminum-air batteries for all vehicles. “We are in discussions with two aircraft manufacturers. It’s not going to be suitable for jets. But it would work in propeller planes, and be suitable for short-haul passenger and cargo flights.”

Jackson says the mistake James Dyson made in his quest to design an electric car was depending on lithium-ion batteries to power it.

“If his cars had been based on aluminium-air fuel cells, the outcome might have been different. Everyone knows that if we are really going to hit the Government’s target of net zero greenhouse gas emissions by 2050, the hardest nut to crack is transport.

“We’re just not going to do that with lithium-ion. Apart from anything else, it’s no use for trucks, which burn vast amounts of fossil fuel. I know we are battling ferocious vested interests but the technological and environmental advantages of aluminium-air are overwhelming — and Britain has a chance to become the world leader in it.”

Danny Corcoran adds: ‘If you want to do something about the environment, you can. You can do it now, with this product.’ Is that true? “We’ll see,” said the Zen master.