Electric vehicles have been widely touted as the future of low-carbon transportation. However, like any technology, the price of electric vehicles is dependent on raw materials. This article will explore how rising raw material costs present challenges for the electric vehicle sector.

The Transportation Sector and Climate Change

Climate change is a pressing existential threat in the 21st century. Historical fossil fuel exploitation has been responsible for global temperature rises of nearly 1% since the pre-industrial era. Since the early 1980s, global temperatures have accelerated.

According to National Centers for Environmental Information, 2013-2021 saw the warmest years since records began. This accelerating global temperature rise is causing more extreme weather events. The 2022 heatwave alone caused the hottest temperatures on record in the UK, with 40.3 oC in Coningsby verified by the UK Met Office.

To meet the net-zero carbon emissions targets agreed upon by international bodies and governments, a radical rethink of how humanity generates and consumes energy is needed.

Transportation is a major contributor to global carbon emissions and is second only to the energy sector. The industry accounts for around 17% of global greenhouse gas emissions, and this is growing as more people and goods are transported around the world than ever before.

Global transportation emits 7.29 gigatons of CO2 per year, according to Statista. Urgent action is needed to reduce this figure and mitigate the industry’s contribution to global climate change.

Electric Vehicles and Low-Emission Vehicles

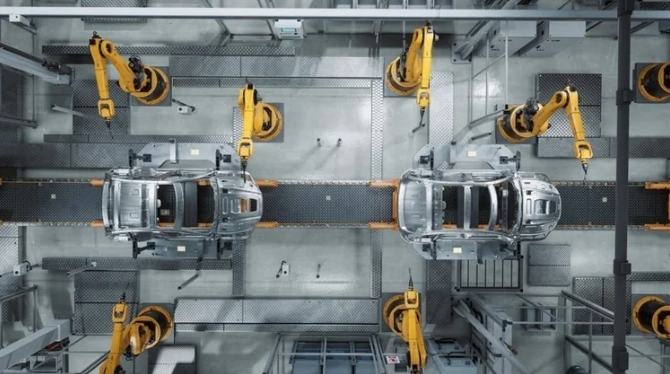

The electric and low-emissions vehicle sector has rapidly expanded in recent years as the transportation industry aims to achieve net zero.

Ongoing efforts to reduce greenhouse gas emissions have spurred investment in green energy, with an average of $600 billion per year spent on strategies to achieve a post-carbon economy.

Between 2017 and 2018, the electric vehicle market saw a 65% growth, with electric vehicles being produced by multiple manufacturers.

Surging demand for these ultra-low-emission vehicles is expected to grow, with 23 million electric passenger vehicles predicted to be produced by 2030.

Rechargeable lithium-ion batteries are at the core of electric vehicle technology, with the worldwide market for these batteries estimated at $7 billion in 2018.

A recent report by UNCTAD has stated that by 2024 the worldwide market for lithium-ion batteries is expected to reach $58.8 billion.

Issues with Critical Resource Supply

Several raw materials are critical for electric vehicles, including lithium, cobalt, and carbon-based materials, such as graphite and nickel.

The supply of many of these materials depends on geopolitical and market forces.

Natural sources of metals, such as lithium, are limited, and the demand for lithium is not restricted to electric vehicles. Many other modern technologies use lithium-ion batteries, including smartphones, computers, and renewable energy technologies, such as photovoltaic solar cells.

The US is a vast market for electronic goods and electric vehicles. Despite this, only 1% of the world’s lithium is mined and processed in the US. Most raw lithium is mined in China, Australia, and Chile. China controls more than 50% of the lithium processed and mined globally.

Other raw materials are limited to a handful of global producers:

Sustainability, environmental issues, and socioeconomic impacts are also associated with raw material production.

Lithium mining, for instance, is incredibly polluting, and in countries such as the Democratic Republic of the Congo, many mining operations are highly dangerous.

Soaring Costs: A Key Challenge for the Electric Vehicle Industry

Ongoing supply chain problems across the entire electric vehicle industry, coupled with high raw material costs, have caused disruptions in recent years. This has led to many manufacturers increasing vehicle costs for consumers to cope with these pressures.

According to AlixPartners, a consulting firm, consumer demand and issues with supply will cause price increases through 2024.

The average new EV price in February 2022 was $60,054, which increased to $60,984 in May, according to car-buying site Edmunds. Average raw material costs per vehicle have spiked to over $8,000, according to AlixPartners. Prices have increased by 140% since early 2020.

If the electric vehicle market is to continue growing, vehicles must be cost-competitive with diesel and petrol vehicles.

According to AlixPartners, the price of raw materials used in electric vehicles is now around 125% of the cost of raw materials used in ICE vehicles.

Battery price rises have come at a sensitive time in the EV market as global automakers launch electric cars and trucks for the mass market. This rise in battery price is one of the main factors in pushing up the initial cost of electric vehicles compared to ICE vehicles.

Lithium metal prices have increased almost tenfold since 2021, the price of nickel has increased by 75%, and cobalt has almost doubled in price since 2020. If the transportation industry is to achieve its net-zero carbon emissions aims, supply chain issues must be solved, and raw material costs must be reduced.

The Future

Analysts are unsure when raw material costs for EVs will fall.

Lithium mines have reported problems meeting growing demand, and countries aim to decrease their reliance on Chinese supply chains.

Proactive solutions are needed to overcome current challenges and ensure the future of the EV industry. They will also help to significantly reduce the transportation sector’s contribution to climate change.