Russia’s NA Dollezhal Scientific Research & Design Institute of Power Engineering (Nikiet - part of Rosatom) has completed the preliminary design of a research molten-salt reactor for the Mining & Chemical Combine (MCC) in Krasnoyarsk as part of a Russia-wide research effort. The draft design is for a reactor plant with an innovative research reactor which uses a circulating molten fuel salt (IZhSR). The work was carried out in cooperation with the National Research Centre Kurchatov Institute and a number of Rosatom enterprises. A detailed R&D programme was drawn up and approved by Rosatom, which will substantiate the design’s technical solutions, then build and put into operation the IZhSR reactor plant at MCC.

IZhSR is designed to develop liquid-salt technologies necessary to create a full-scale liquid-salt reactor to burn minor actinides (long-lived nuclear waste) contained in used nuclear fuel from thermal reactors. As part of the R&D programme, substantiation of the structural materials for the reactor plant and equipment, the use fuel processing module, the technology for preparing fuel and washing salts and other technologies are already underway. The next milestones of the project will be justification of investment in a nuclear research facility with IZhSR and the development of its technical design.

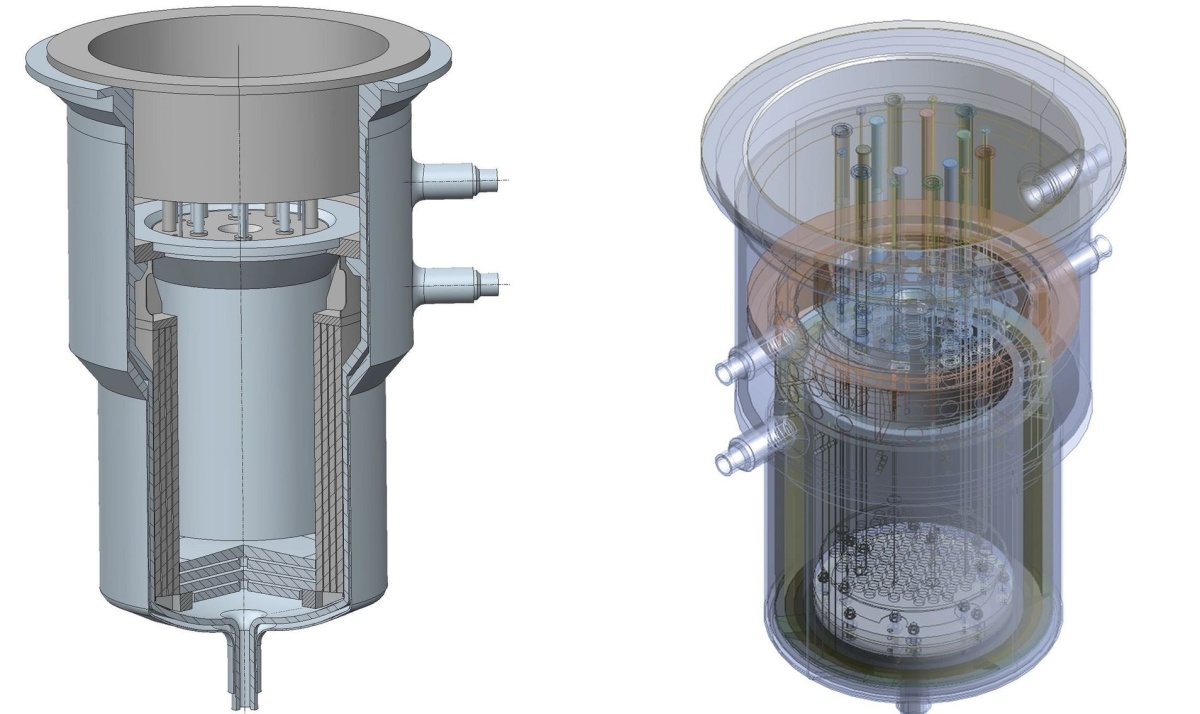

In the IZhSR, the active zone is formed by a homogeneous molten mixture of fluorides, salts of lithium, beryllium, and fissile material. The fuel composition is used both as a core fuel and as a primary coolant. IZhSR will include natural safety systems and the temperature and void coefficients are negative.

Rosatom in March 2021 announced a tender for the development and demonstration of key technological solutions for the creation of a research molten salt reactor and used nuclear fuel reprocessing module. The cost of the work planned for 2021 was estimated at RUB369 million ($5m), and the funds would be allocated from the federal budget. Rosatom has said the IZhSR would be launched in 2031 at MCC and the technical design of the installation should be completed in 2024, to obtain a construction licence in 2027. The thermal power of the planned reactor is no more than 10MW. Once the technology is developed and tested in the IZhSR construction of an industrial scale version is being considered with a power of 1.5-2.5GWt. This is part of the federal project "Development of new materials and technologies for advanced energy systems" under Russia’s Integrated Programme "Development of Engineering, Technology & Scientific Research in the Field of the Use of Atomic Energy.

Earlier in December, Tomsk Polytechnic University hosted a scientific and technical seminar on molten salt reactors bringing together leading experts from various Rosatom organisations and the Russian Academy of Sciences to discuss the IZhSR. The seminar atracted representatives of all of Russia’s major nuclear research organisations including: MCC, Rosatom’s Science & Innovation section, Nikiet, the AA Bochvar Research Institute of Inorganic Materials (VNIINM - part of TVEL), the Research Institute of Atomic Reactors (NIIAR), the All-Russian YI Zababakhin Scientific Research Institute of Technical Physics (VNIITF), The Urals Federal University (UrFU), the VG Khlopin Radium Institute, the Nuclear Container Corporation, and IT company GK Neolant.

Discussions covered the current state and prospects of the project, calculation tools for modelling the IZhSR, preparation of the fuel salt and its irradiation, design materials for reactor equipment, used nuclear fuel reprocessing module technologies and much more.

MCC has already manufactured the first batch of fuel salt for the planned IZhSR. An experimental installation for producing fuel salt based on lithium and beryllium fluorides was launched at the end of 2021. This followed a number of experimental design and research work carried out under state contracts and targeted financing of about RUB2 billion.

MCC said, working with Nikiet it had prepared the initial data for the development of a control system for the reactor, developed a hardware and technology scheme for the used fuel processing module, and chosen the best layout options. A single information space was set up for all project participants to facilitate the exchange documents and information.

Organisations and instiutes actively co-operating on the project include the Kurchatov Institute, the Institute of High-Temperature Electrochemistry of the Ural Branch of the Russian Academy of Sciences, the IP Bardin Central Research Institute of Ferrous Metals (TsNIIchermet) VNIITF, OKBM Afrikantov, VNIINM, the Khlopin Radium Institute, NIIAR, and UrFU.

For example, TsNIIchermet has manufactured a pilot batch of sheets and pipes from high-nickel alloy for possible use in the reactor vessel, main circulation pump, heat exchangers and pipelines. The Kurchatov Institute has studied the material for corrosion resistance - the samples were kept in contact with the melting of salts under conditions simulating the intermediate circuit of a nuclear installation. The Institute of High Temperature Electrochemistry is studying the physical properties of the fuel salt including viscosity, density, thermal conductivity and heat capacity. Mock-ups of pump and heat exchanger were made by OKBM Afrikantov.

UrFU, which has been researching molten salt for over 50 years, is collaborating closely with MMC. Together they are developing a plant to synthesise and purify fuel salt of lithium fluorberylate and an installation is to study the corrosion resistance of structural materials for the used fuel processing module.

Molten salt reactor research and development is underway in several other countries including the USA, Canada, the UK, the Netherlands. These projects involve a number of private companies that are designing facilities using government grants and private investment. However, only in Russia are the combined efforts of leading state research organisations being brought together to push forward this technology.