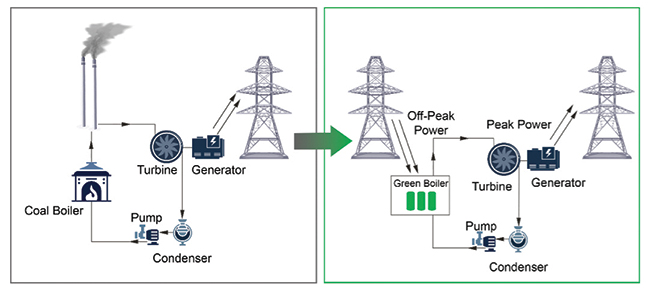

4. The figure on the left illustrates a coal plant cycle. Holtec’s proposed Green Boiler cycle is illustrated on the right. Courtesy: Holtec International

The Green Boiler, is essentially a large capacity modular energy storage system that comprises a “large thermal reservoir filled with engineered salts spiked with infrared emitter particles,” Joe Delmar, Holtec’s senior director of Government Affairs and Communications, told POWER in May. Each module can store about 60 MWh of thermal energy with a standard design target of 12 hours.

The system consists of three large heavily insulated cylindrical vessels—the pre-heater, the boiler, and the superheater—which are substantially filled with engineered salts and equipped with specially configured tubes to convert feedwater into superheated steam. Each vessel contains a “tube bundle configured to permit significant expansion and contraction” during the plant’s operation without significant cyclic fatigue and withstand solidification of the enveloping thermal repository as its heat is delivered to produce cycle steam.

“The technology utilizes bayonet-type electric heaters to heat the engineered salts,” using surplus grid power, Delmar added. That thermal energy can then be used to run the existing plant’s turbogenerator to produce electricity on demand, he said. The Green Boiler can deliver steam at the same enthalpy and pressure as that used by the plant’s existing turbogenerator to generate power when needed, he noted.

The company completed a conceptual design of the Green Boiler system about a year ago, and Holtec has since filed a provisional patent on the system. “Subsequently detailed design, including material selection, thermal analyses, fabricability, site deployability, and maintainability evaluations for a generic Green Boiler were carried out,” Delmar said. “At this point in time, the Green Boiler system can be readily customized for an existing coal-fired plant.”

Based on Existing Technology

While the Green Boiler has not yet been tested at a power plant, it is based on existing technology. Notably, it uses much of an existing coal plant’s infrastructure, with the exception of the coal burner, smoke stack, coal yard, and ash handling systems. “We are ready to build and deploy at a willing site but don’t have a firm contract yet,” Delmar said. However, “Holtec is in extended discussions for a pilot plant in the U.S. Therefore, we expect an abundance of interest from the operators of coal-fired plants,” he said.

This version of the Green Boiler “is expressly focused to re-purpose the retiring coal-fired plants,” Holtec said. “We believe the market in the U.S. and overseas will be driven by the global imperative to reduce carbon and other pollutants that are making coal-fired plants environmentally untenable,” said Delmar. “Green Boiler in its present form utilizes the surplus power from the grid to build its thermal inventory, which can be tapped to produce electrical power during the period of heightened consumer demand,” he noted. “The current version seeks to use the existing turbogenerator at the fossil plant to produce power. Thus, the energy will be sold to meet peak demand and hence a favorable price. We fully expect the local and federal governments to incentivize this technology with appropriate carbon credit, as some governments already do.”

The economics and flexibility could further benefit from co-locating an SMR-160, Holtec’s 160-MWe small modular reactor (SMR), at a Green Boiler–converted coal plant site, Delmar noted. However, Holtec is also separately developing a greenfield site system that could integrate a Green Boiler with an SMR-160 or a PV solar collector system using a Brayton cycle-based energy generation system.

The power cycle could yield cycle efficiency in the range of 55% (compared to about 35% from the Rankine cycle), Delmar noted. “We also contemplate the power generation to be coupled with the supply of process steam and produce the hydrogen fuel where needed. Ultimately, we expect the Green Boiler to sit at the center of a mini-grid to meet the local electric, process steam, and hydrogen demands,” he said.