A new lithium-ion battery works at frigid temperatures of -40 °C all the way to a scorching high of 50 °C. With a cathode made of sulfur, the new lithium-sulfur battery could also pack more energy than is possible with today’s chemistries.

The batteries could increase the driving range of EVs in cold climates. They could also be used in satellites, spacecraft, high-altitude drones, and submarines. “By largely expanding the operation window for lithium batteries, we can provide more robust and resilient battery chemistry for applications beyond EVs,” says Zheng Chen, a professor of nanoengineering at the University of California, San Diego.

Today’s batteries, with their graphite anodes and lithium metal oxide cathodes, don’t handle extreme temperatures very well. High temperatures exacerbate the already highly chemically active environment inside a battery cell, causing side reactions that decompose the electrolyte and other battery materials, resulting in irreversible damage. Low temperatures, meanwhile, thicken the liquid electrolyte, so lithium ions move through it sluggishly, leading to power loss and slow charging.

Insulating the battery or novel ways to heat it up from the inside help address the cold temperature issues. Researchers have also previously engineered the electrolyte to expand battery temperature range, but that improves performance either at low or high temperatures, not both at once.

The heart of the new extreme-temperature battery that Chen and his colleagues have reported in the Proceedings of the National Academy of Sciences is a new electrolyte formulation. They make it by dissolving a lithium salt in dibutyl ether (DBW) solvent. Unlike the ethylene carbonate solvent used today in batteries, DBE does not freeze at temperatures down to -100 °C, says Chen. It also does not evaporate easily. Plus, DBE molecules bind weakly to lithium ions, so lithium ions move through it more freely, even in freezing temperatures.

The new electrolyte also works well in a lithium-sulfur battery. These batteries, with a lithium metal anode and sulfur cathode, promise at least twice the energy density of conventional lithium-ion batteries. Plus, their use of low-cost sulfur in the cathode is a big advantage. “Their performance-to-price ratio is very high,” Chen says.

But lithium-sulfur batteries typically last only for 40 to 50 charging cycles. The reactive sulfur cathodes dissolve during battery operation, and lithium metal anodes tend to form spiky growths called dendrites that can pierce the battery separator, causing a short circuit. These issues get worse at high temperatures.

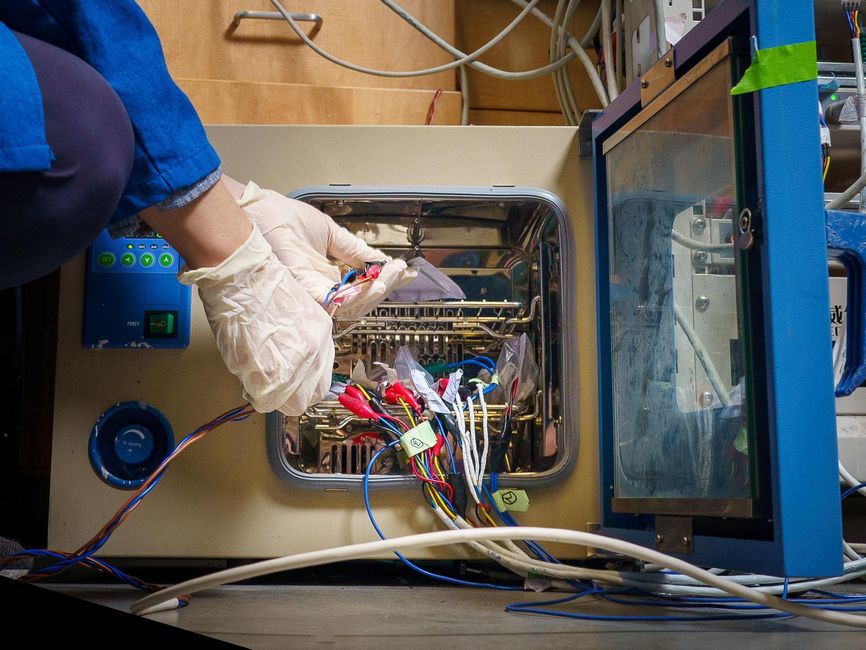

DAVID BAILLOT/UC SAN DIEGO JACOBS SCHOOL OF ENGINEERING

The UCSD team addressed the sulfur cathode degradation by attaching the sulfur to a plastic substrate. Meanwhile, the new electrolyte allows uniform transport of lithium ions so they don’t get a chance to stick together and form dendrites.

Prototype pouch cells that the team tested lasted through 200 cycles and retained more than 87 percent of their original capacity at -40 °C. At 50 °C, the battery’s capacity increases by 15 percent because, says Chen, the higher temperature increases the charge transfer and the diffusion of lithium ions through the electrolyte and onto the electrodes, “so it pushes the limit of the cell capacity and energy further.”

That increase in capacity is not necessarily a good thing since it can overburden the cell, he says. To get around that, the researchers will have to improve the battery’s chemistry further so it can sustain many more charge cycles. They also plan to increase energy density with more cell engineering. Right now, it’s only slightly higher than today’s lithium-ion batteries, and not nearly what lithium-sulfur promises in theory. “We could increase the energy density by 50 percent at least,” Chen says. “That’s the hope, that’s the promise.”