Nuclear energy, however, carries a dreaded stigma. After disasters such as Chernobyl, Three Mile Island, and Fukishima, the public is acutely aware of the potential, though misguided, dangers of nuclear energy. The cost of nuclear generation is on the rise–a stark contrast to the decreasing costs of alternative energy forms such as solar and wind, which have gained an immense amount of popularity recently.

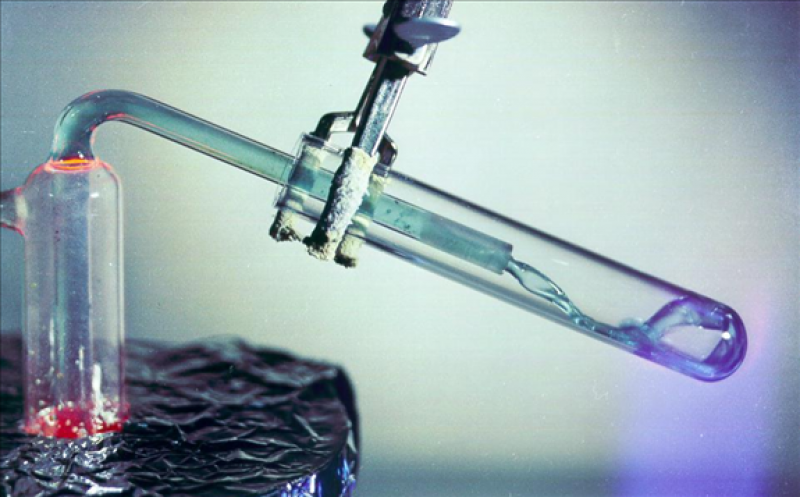

This trend could continue until market forces make nuclear technology obsolete. Into this dynamic comes a resurgence in nuclear technology: liquid fluoride thorium reactors, or LFTRs (“lifters”). A LFTR is a type of molten salt reactor, significantly safer than a typical nuclear reactor. LFTRs use a combination of thorium (a common element widely found in the earth) and fluoride salts to power a reactor.

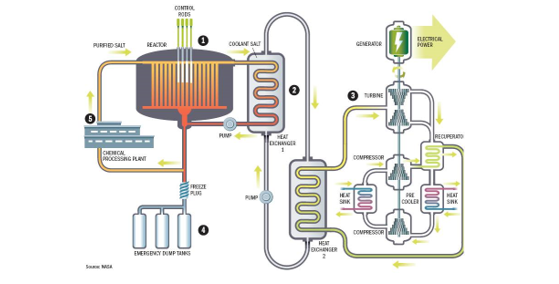

A typical arrangement for a modern thorium-based reactor resembles a conventional reactor, albeit with notable differences. First, thorium-232 and uranium-233 are added to fluoride salts in the reactor core. As fission occurs, heat and neutrons are released from the core and absorbed by the surrounding salt. This creates a uranium-233 isotope, as the thorium-232 takes on an additional neutron. The salt melts into a molten state, which runs a heat exchanger, heating an inert gas such as helium, which drives a turbine to generate electricity. The radiated salt flows into a post-processing plant, which separates the uranium from the salt. The uranium is then sent back to the core to start the fission process again.

Thorium reactors generate significantly less radioactive waste, and can re-use separated uranium, making the reactor self-sufficient once started. LFTRs are designed to operate as a low-pressure system unlike traditional high-pressure nuclear systems, which creates a safer working environments for workers who operate and maintain these systems. Additionally, the fluoride salts have very high boiling points, meaning even a large spike in heat will not cause a massive increase in pressure.

Both of these factors greatly limit the chance of a containment explosion. LFTRs don’t require massive cooling, meaning they can be placed anywhere and can be air-cooled. If the core were to go critical, gravity would allow the heated, radiated salt to spill into passive via underground fail-safe containment chambers, capped by an ice plug that melts upon contact.

LFTRs provide numerous benefits. Any leftover radioactive waste cannot be used to create weaponry. The fuel cost is significantly lower than a solid-fuel reactor. The salts cost roughly $150/kg, and thorium costs about $30/kg.

If thorium becomes popular, this cost will only decrease as thorium is widely available anywhere in the earth’s crust. Thorium is found in a concentration over 500 times greater than fissile uranium-235. Historically, thorium was tossed aside as a byproduct of rare-earth metal mining. With extraction, enough thorium could be obtained to power LFTRs for thousands of years. For a 1 GW facility, material cost for fuel would be around $5 million. Since LFTRs use thorium in its natural state, no expensive fuel enrichment processes or fabrication for solid fuel rods are required, meaning the fuel costs are significantly lower than a comparable solid-fuel reactor. In an ideally working reactor, the post chemical reprocessing would allow a LFTR to efficiently consume nearly all of its fuel, leaving little waste or byproduct unlike a conventional reactor. Lastly, a thorium plant will operate at about 45 percent thermal efficiency, with upcoming turbine cycles possibly improving the overall efficiency to 50 percent or greater, meaning a thorium plant can be up to 20 percent more efficient than a traditional light-water reactor.

LFTRs do present a few challenges. There are significant gaps in the research and necessary materials for LFTRs. The post-processing chemical facilities, which would separate uranium from the molten salts for re-use, haven’t been viably constructed yet. Each reactor would require some highly enriched uranium (such as uranium-235) to start the reactor, which is very expensive. Scientists suggest a $5 billion investment over the next five years could net a viable reactor solution in the United States, but with limited funding for thorium, it is difficult to see this vision come to fruition. Other countries have made preliminary investments towards building thorium reactors.

The public stigma about nuclear is real, and that must be overcome first before lawmakers will take action, as money needs to be allocated for research and development to continue on LFTRs in the United States. Without public and scientific support, it will be difficult to move forward with this technology. Education is needed to help push the agenda for thorium, spread information about thorium-based reactors, and educate the public about their safety. Resources to learn more about thorium and LFTRs include websites such as The Independent Global Nuclear News Agency and World Nuclear News, or conferences such as the Thorium Energy Conference.

Thorium reactors are a different way to generate electricity that could benefit the world. More efficient than their fossil fuel counterparts, safer than a conventional nuclear plant, and generating no carbon emissions as a byproduct, LFTRs are a viable solution for the future of our world’s energy needs.