The Lightweight Manufacturing Centre (LMC), as part of a consortium, is developing an ultralight and sustainable wind turbine blade that will produce up to 9% more energy than conventional blades.

The LMC is part of the National Manufacturing Institute Scotland (NMIS), operated by the University of Strathclyde, Glasgow, Scotland. The project is being funded through Innovate UK.

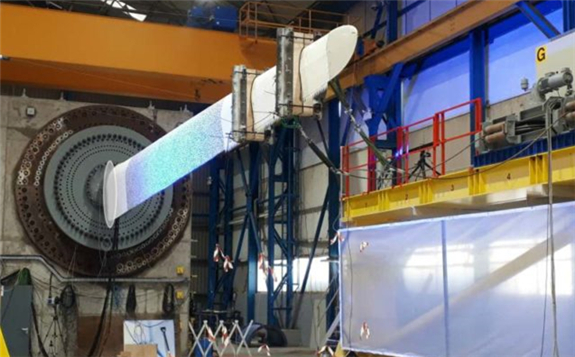

Developed by Edinburgh based ACT Blade, the new technology involves replacing the heavier glass fibre design traditionally used for wind turbine blades with a lighter composite structure, wrapped in a sail-like textile.

The LMC, together with the University of Sheffield’s Advanced Manufacturing Research Centre (AMRC) and the Offshore Renewable Energy (ORE) Catapult, is supporting ACT Blade to develop the blade and bring it to market.

A lighter blade allows for 10% more length, which, in turn, generates up to 9% more energy from the same wind turbine. The technology could be a disruptor for the offshore wind industry, helping to make offshore wind – already one of the cheapest forms of large-scale energy generation in the UK – even cheaper and easier to harness.

Professor Iain Bomphray, Director of the Lightweight Manufacturing Centre, said: “This is the first of its kind in the world. ACT Blade has developed an entirely new type of blade made of composite materials and a textile shell that offers significant cost and sustainability benefits. Manufacturing costs are also 30% lower than for conventional blades and they don’t require finishing and painting, which is a time consuming and polluting process. The blade is also partly recyclable.

“We were keen to apply the lightweighting expertise and experience we have here at the LMC to the ACT Blade concept, also helping the team to design, test and ultimately manufacture this innovative technology.”

The prototype was completed in February this year and in April, ACT Blade announced that it had successfully completed static tests at ORE Catapult’s National Renewable Energy Centre in Blyth. The blade is now undergoing testing of one million cycles in each direction, with ORE Catapult engineers monitoring its performance.

Dr Sabrina Malpede, ACT Blade CEO, said: “This ultralight blade has the potential to be completely disruptive to the renewables sector, allowing for substantial cost savings and increased production of wind energy. Working with the LMC has allowed us to tap into its composite capabilities and take our ACT Blade concept from design through to manufacture. Now, we need to see how it performs in a real environment.”

Lightweighting refers to the process of making products or parts lighter to reduce costs, energy expenditure and carbon emissions. The principles are of interest across multiple sectors from aerospace and automotive to defence and renewables.

John Halfpenny was technical Lead at the AMRC Composite Centre and part of the team that worked on the development prototype blade alongside High Value Manufacturing (HVM) Catapult colleagues at the LMC. Halfpenny said: “Through cross-Catapult collaboration, we have applied our leading expertise in lightweight, advanced technologies, composites design and manufacture allowing us to take ACT Blade’s innovative idea and develop and improve the design to increase strength, stiffness and stability of the blade, and assist with the novel manufacturing process.”